|

Saprankov |

|

Diaz |

|

Home

>

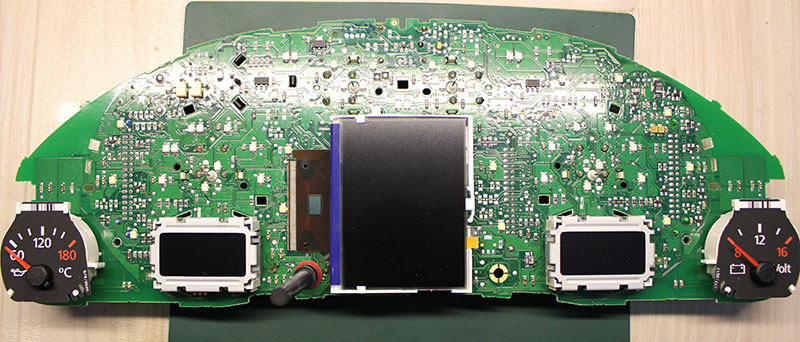

Audi - A6

C5 4B |

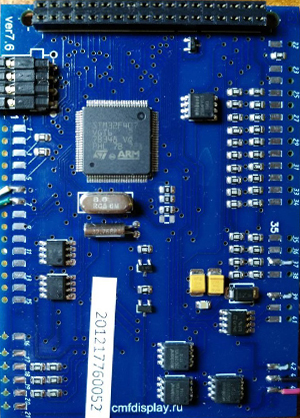

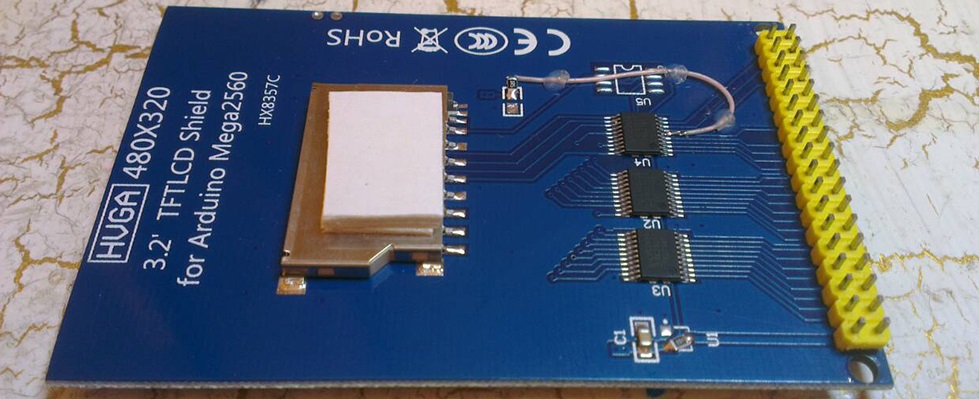

3DColorMFD

ver.

7.6 |

|

|

Audi

A6 C5 4B |

|

|

You will need:

|

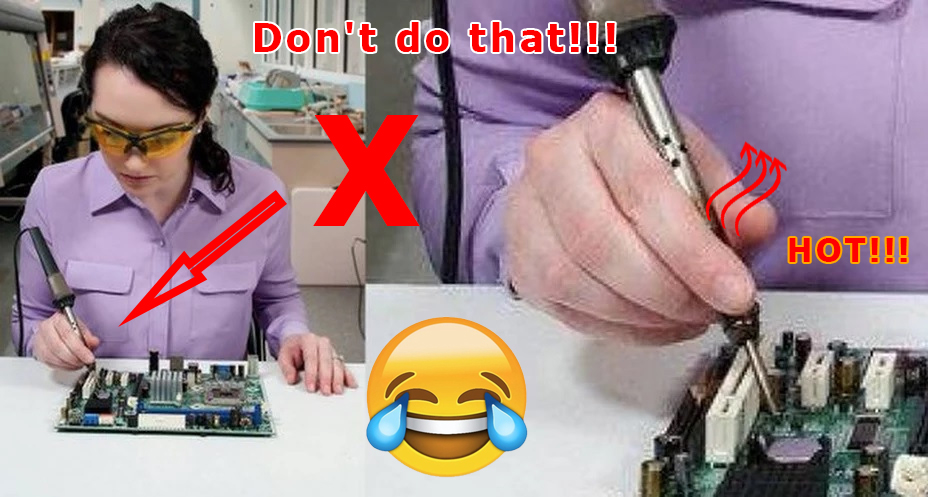

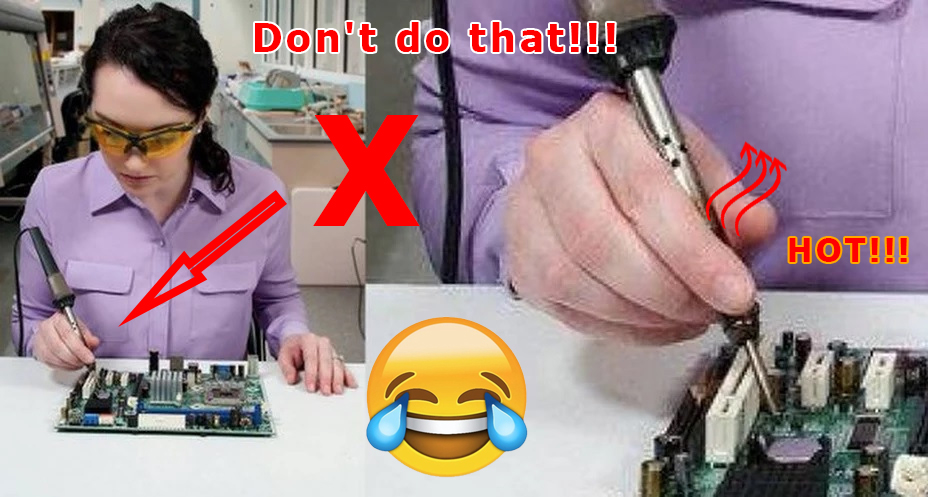

Safety

precautions

DO NOT! |

|

|

ATTENTION!!!

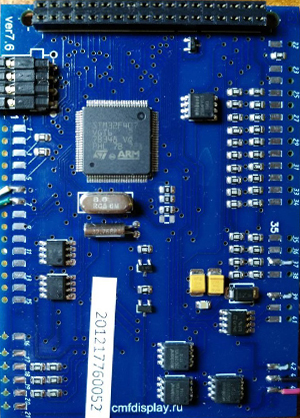

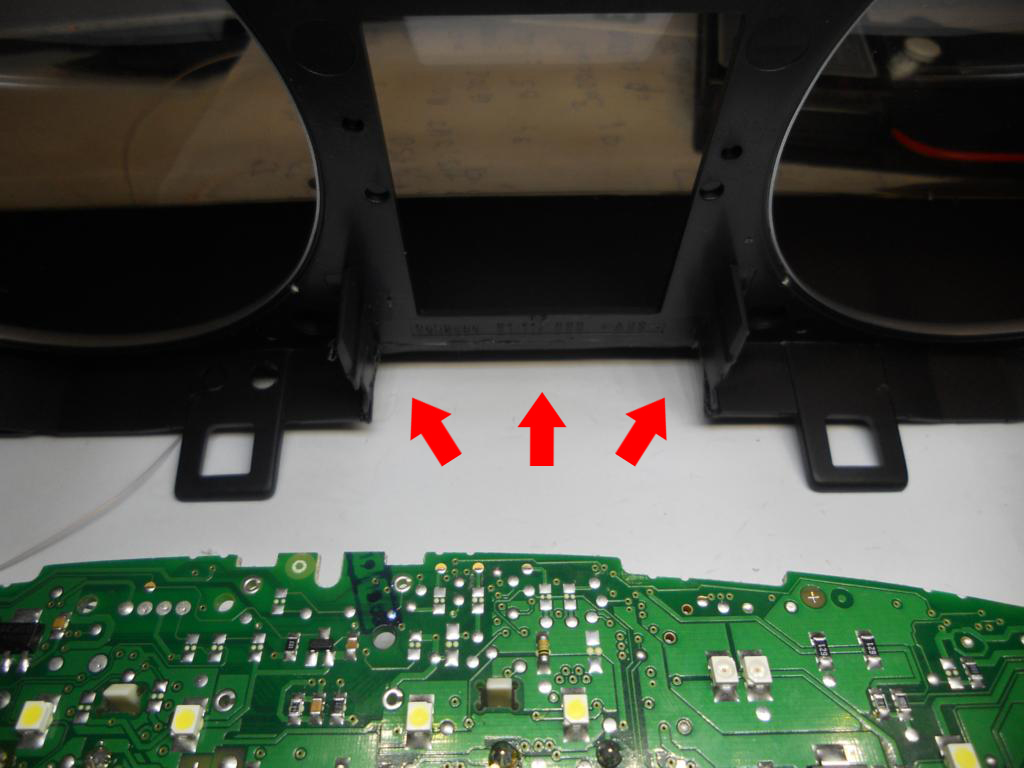

When installing a color MFD, there are 3 most important points.

1. You need to configure the

power supply to 5.5v.

The MFD operates at a voltage of

5.5v.

When you connect the power supply to the MFD

you should make sure that the output

of the contacts is 5.5v,

otherwise it will damage the processor! Paragraph

18

2. It is necessary to cut the

power paths going to the pins 17,18,19,

then check that they are not voltage-free, you need to supply power

to the cluster

and check with a tester, one probe into the ground of the second to

each pin 17,18,19.

Should be 0v . Paragraph

10

3. You need to rinse all the

soldering points. Install very carefully.

After soldering the wires, it is essential to rinse the soldering

points with special flushing agents

or isopropyl alcohol. During washing, do not allow alcohol to enter

the display or under the display and its board!

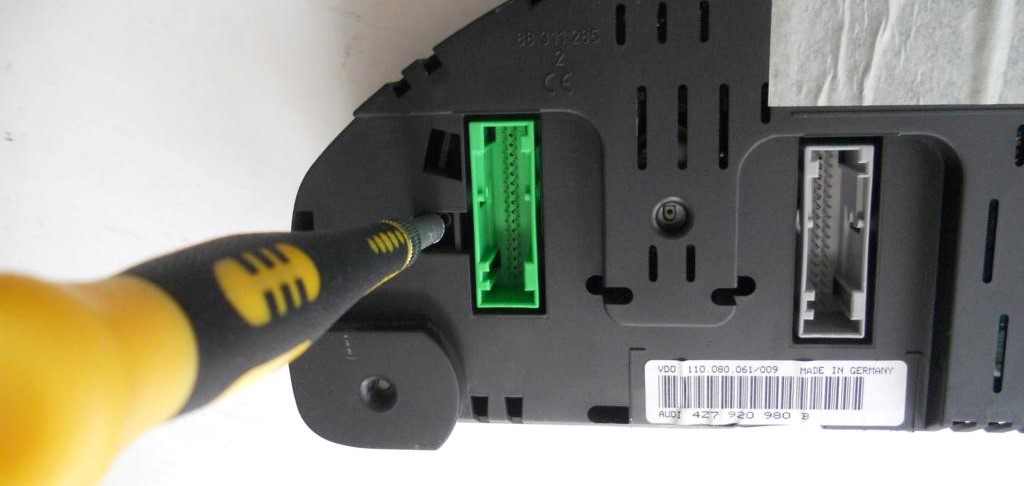

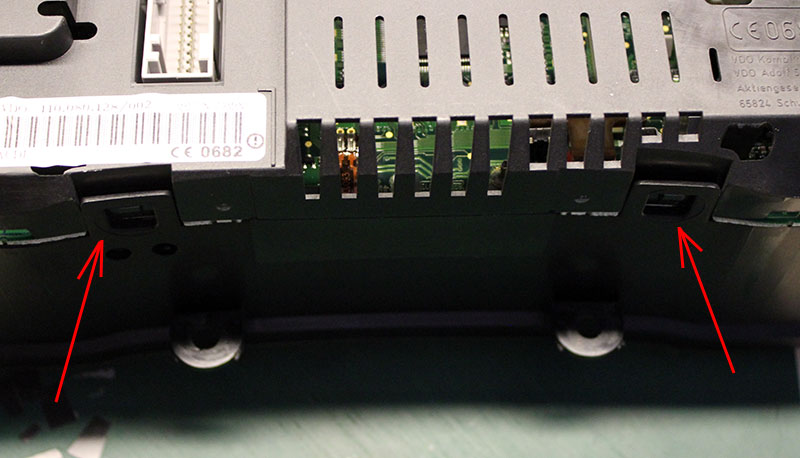

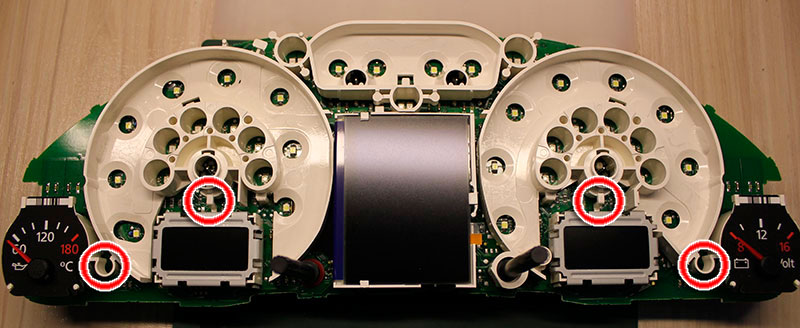

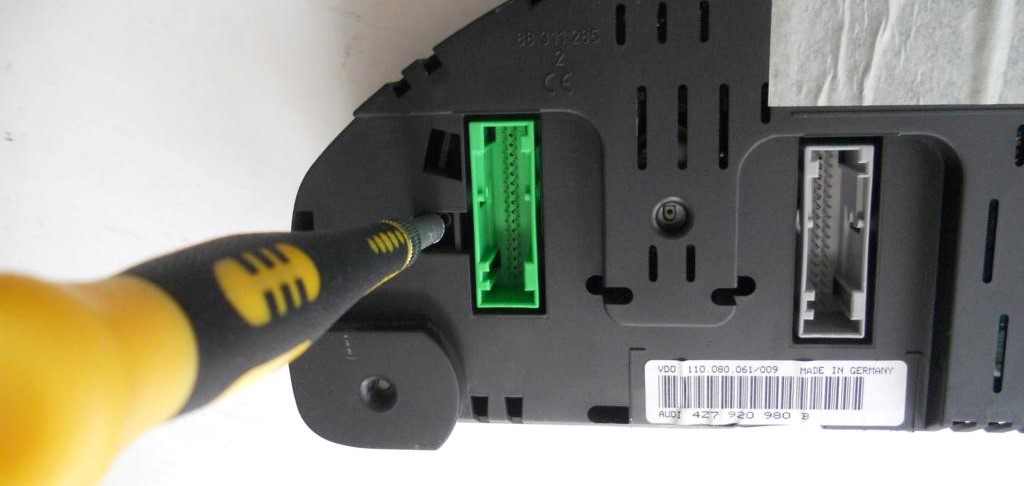

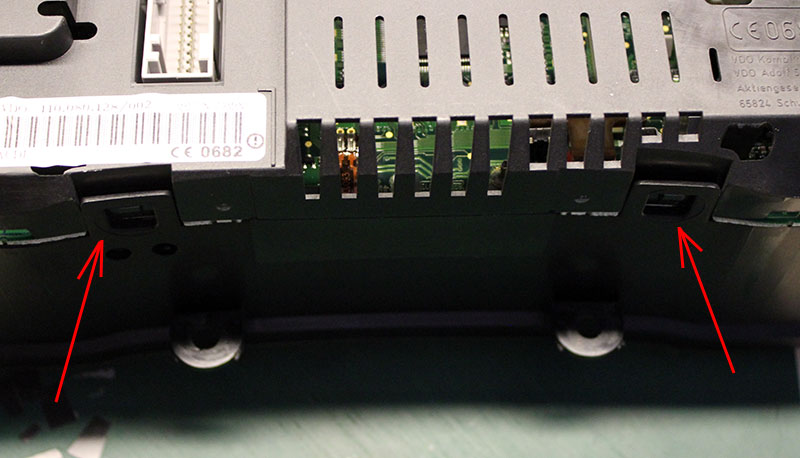

1.

Disassemble

the cluster.

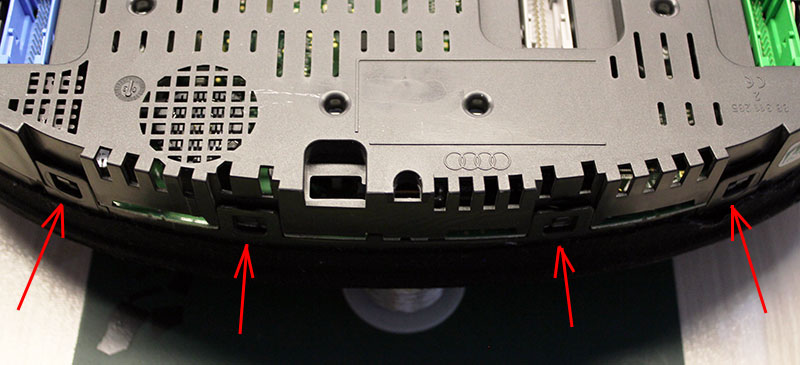

With a

screwdriver torx T10, unscrew the two screws edges

on the rear of the instrument panel.

Bend

all the latches neatly remove the front of the case with glass

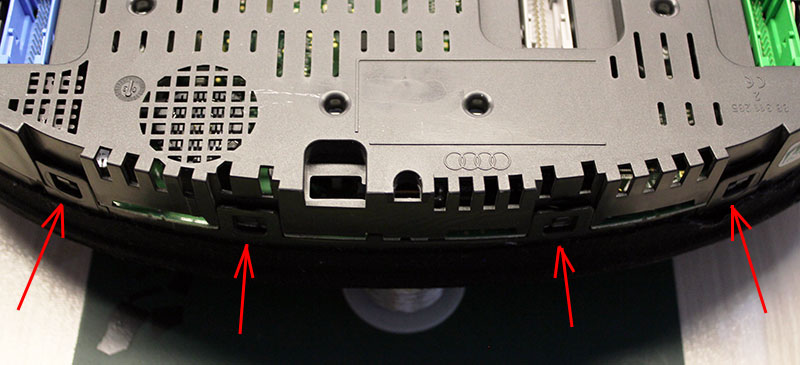

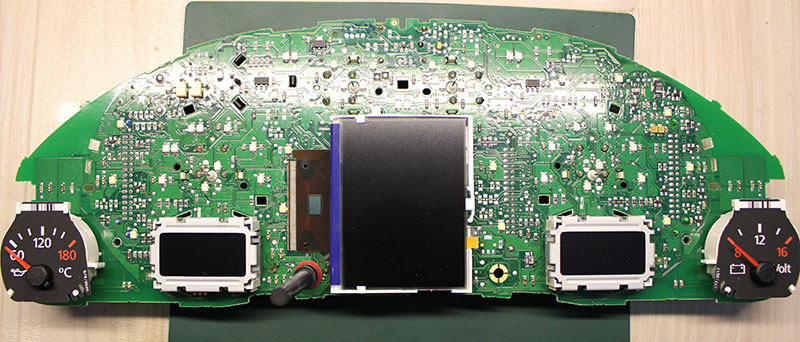

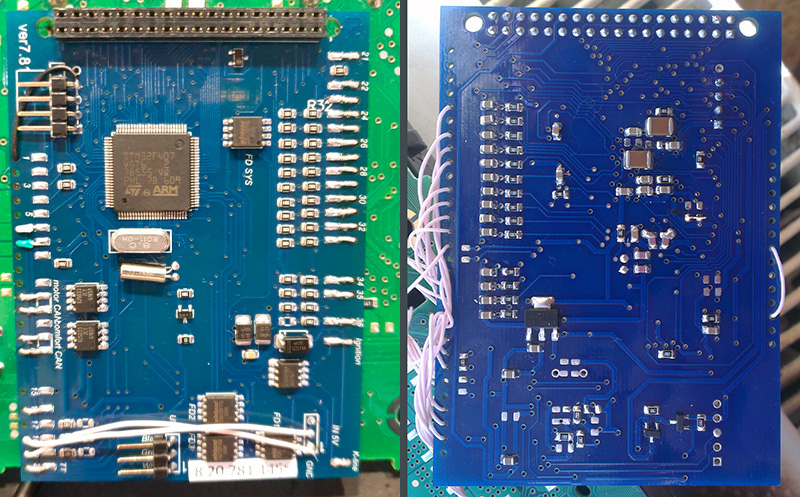

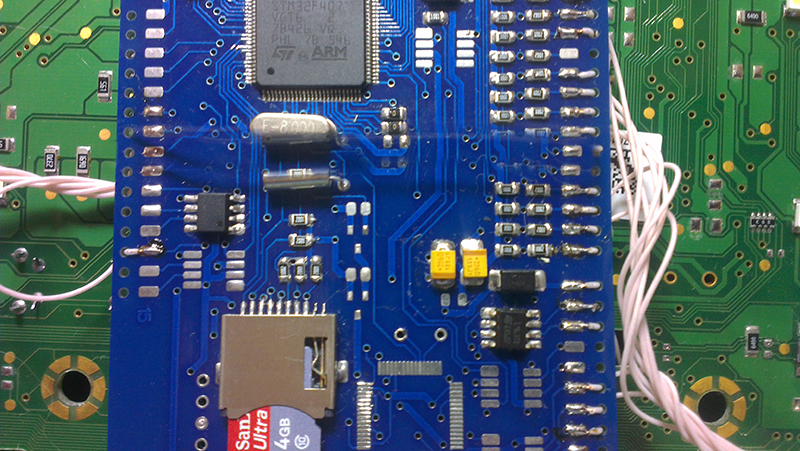

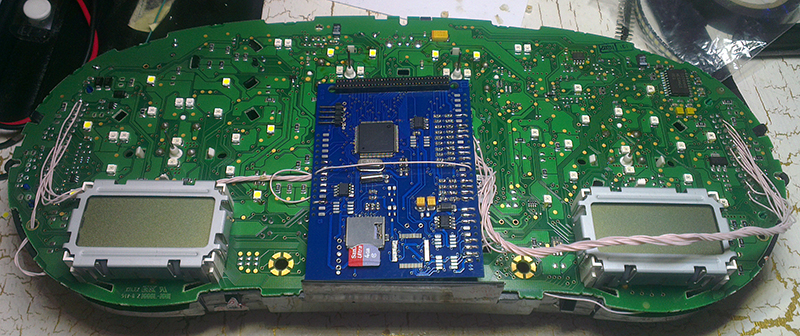

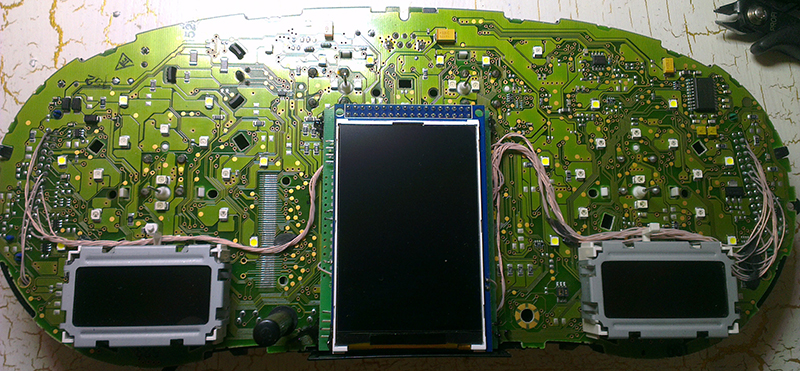

View from above

Bottom view

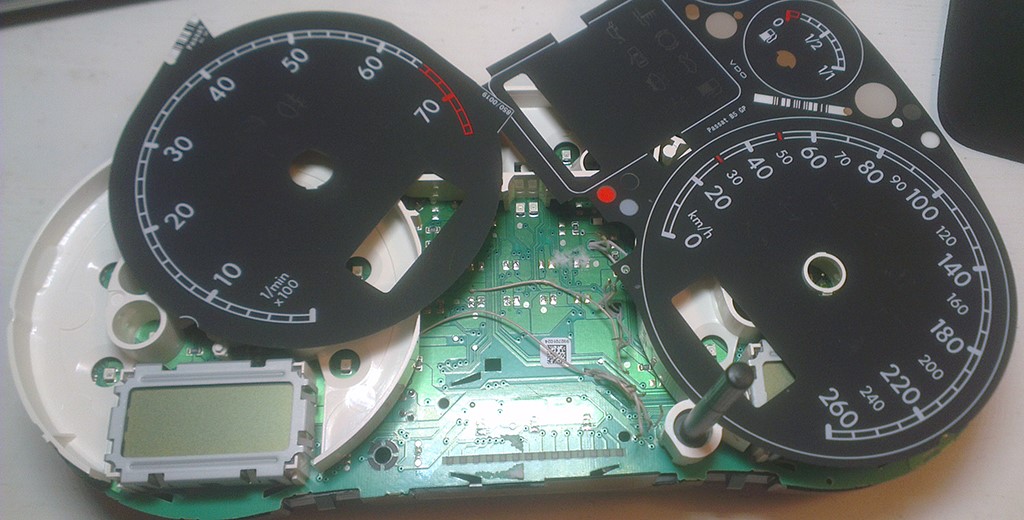

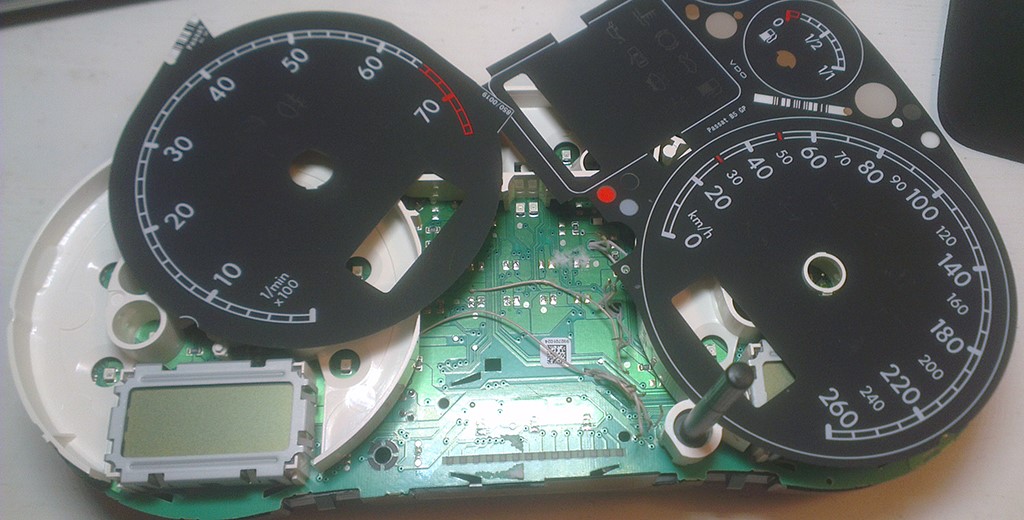

1. Remove

the arrows (scroll counter-clockwise and simultaneously pull

ourselves).

Either Using

knives for oil or spatula, shoot the arrows from their shafts. It

is necessary to put

A

cardboard or napkins between the nomes and the base of the device to

avoid damaging it. Necessary

Pull

the arrows up to yourself.

2. Then

remove the substrate.

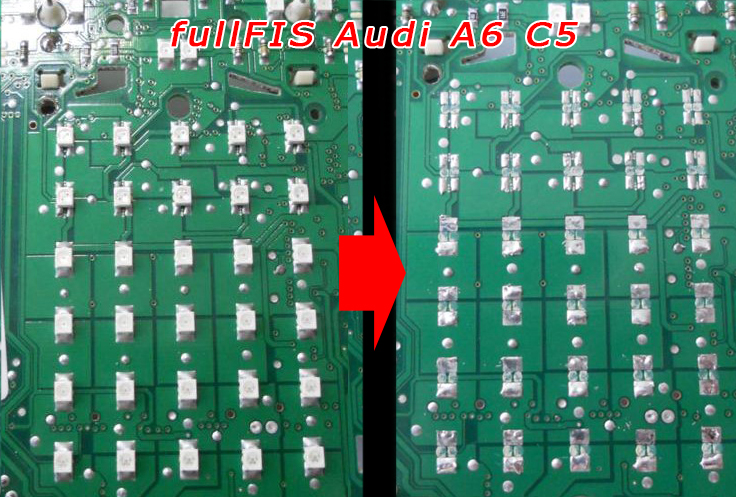

3. Cut

the jumpers, we work carefully, so as not to damage the board.

It

should look like this:

5. Remove the excess.

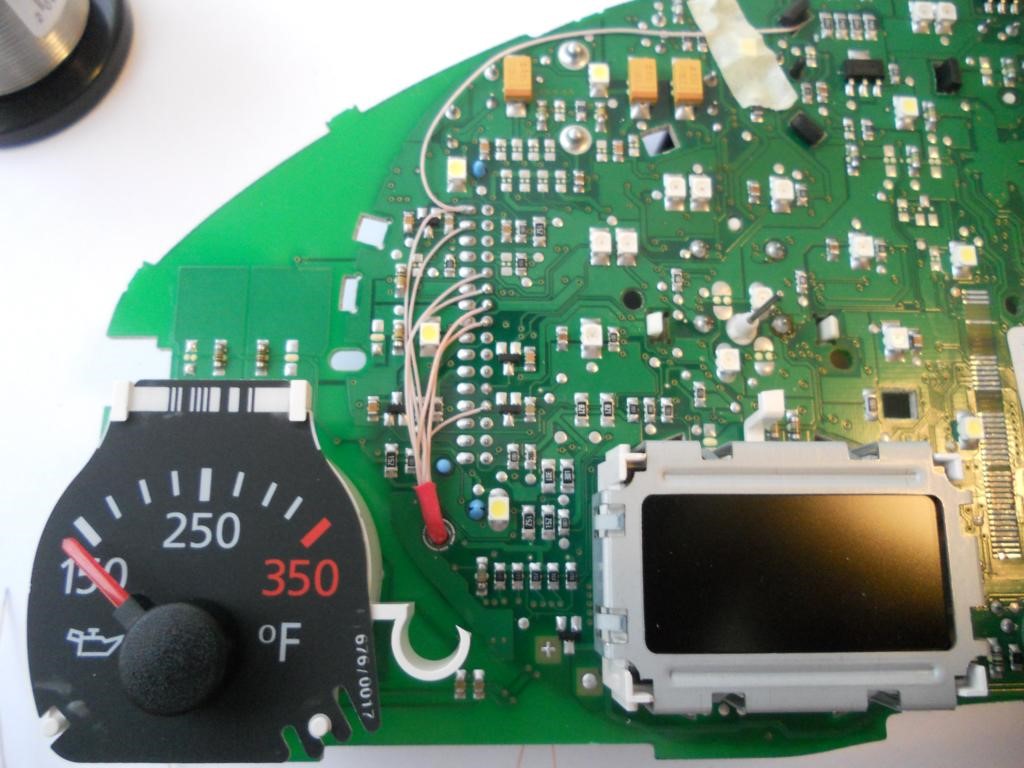

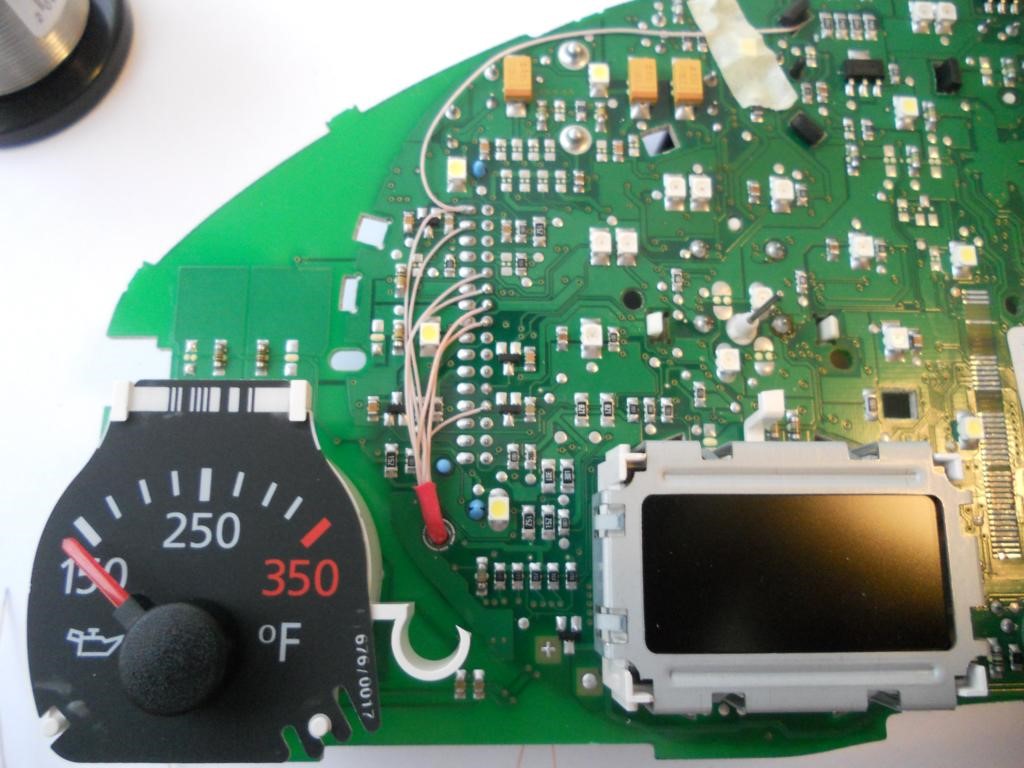

On clusters with fullFIS, a temperature sensor is installed, it can

be removed with a soldering iron or simply cut off the sensor tape

in any convenient place so that it does not interfere

later.

It is necessary to remove the display by gently

heating the loop with which it is soldered to the board, do not tear

off the display as you can damage the dashboard board.

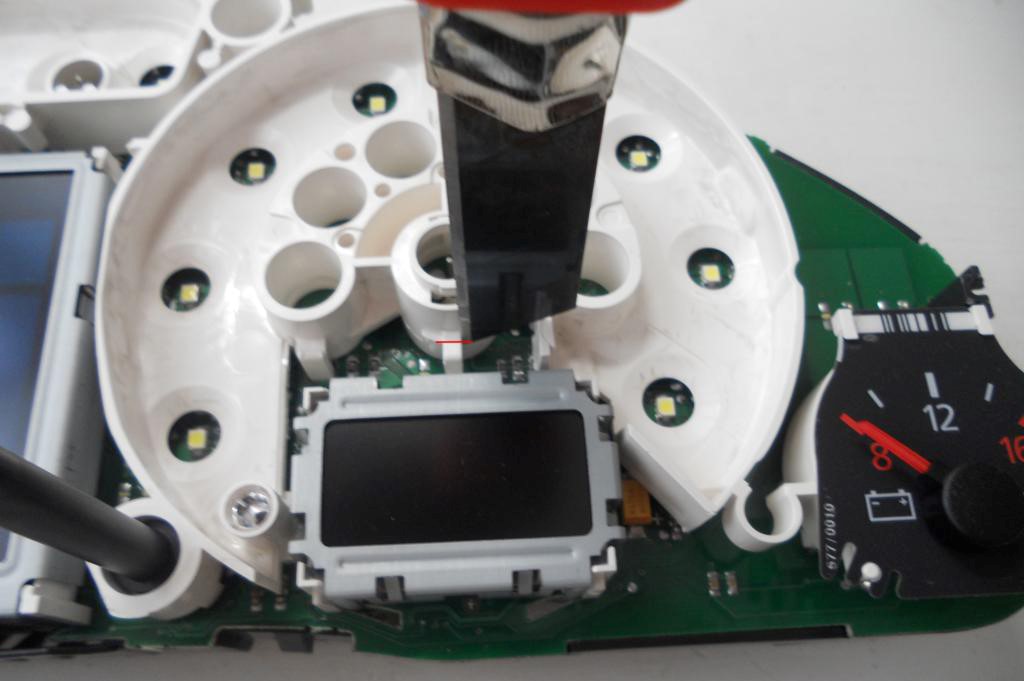

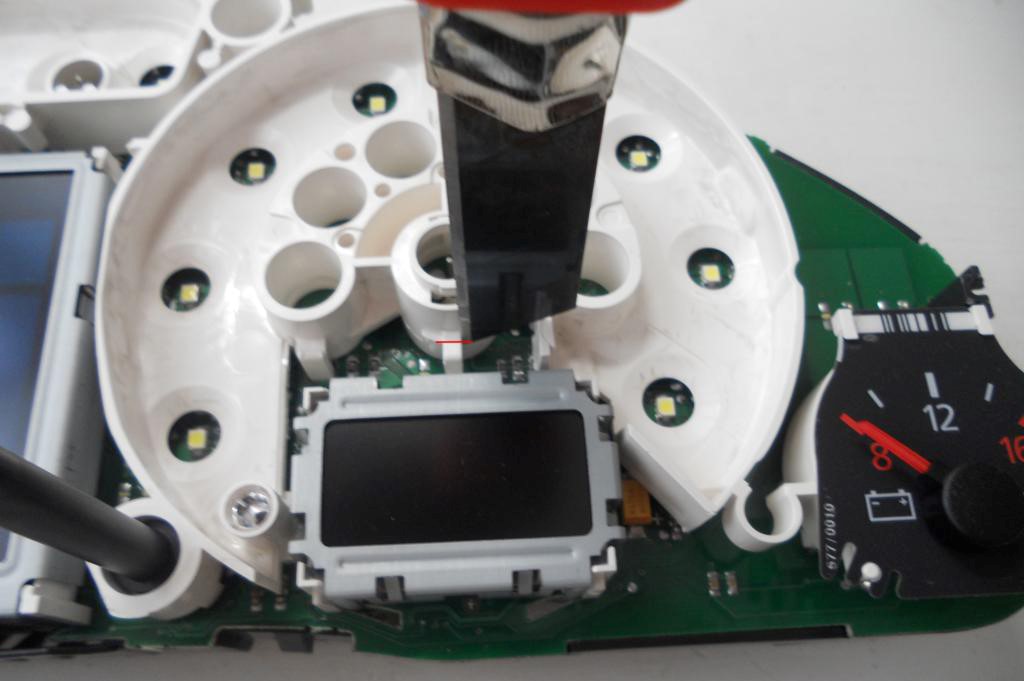

6.

With

the help of pliers we bend the metal clamps restraining

fullFIS display.

7.

Remove

the white diffuser. On

the back of the board, are visible white plastic latches, bend them with your fingers and take out the

white plastic

The basis of the display.

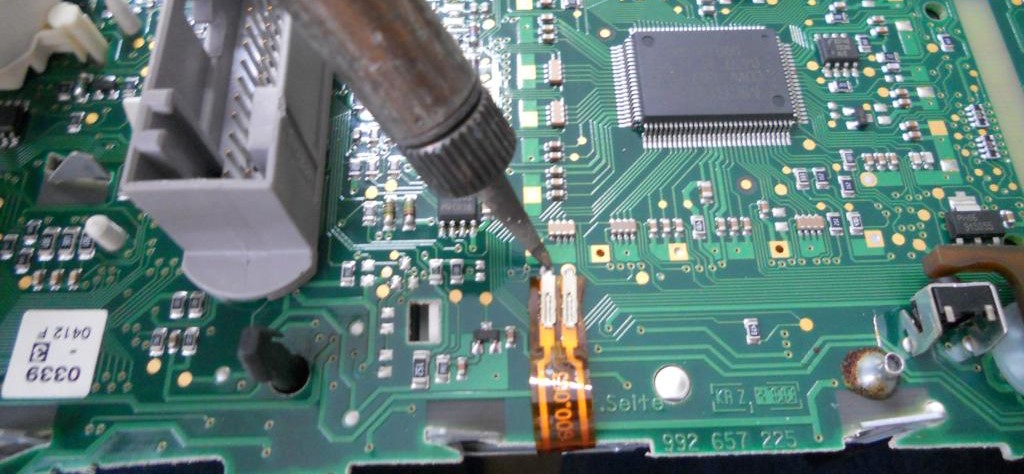

8. We

solder the plume of the standard display and remove it.

On

some instrument panels, the plastic base of the standard display is

soldered to

the board quite seriously, to dismantle it is best to remove the tin

from

using a soldering iron and a special vacuum.

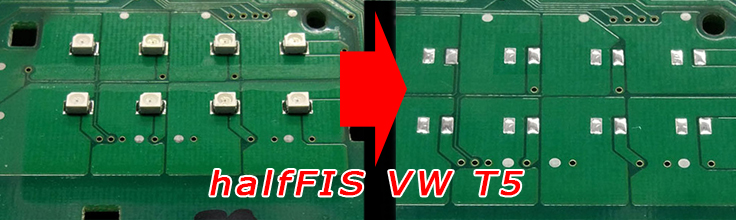

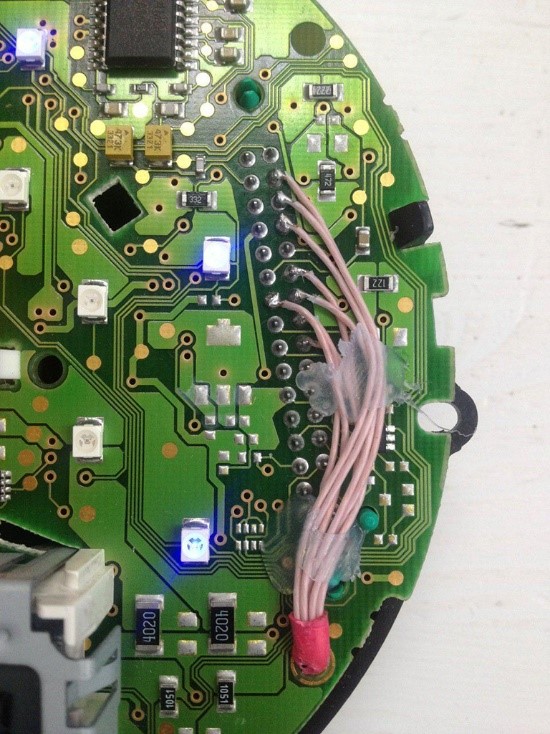

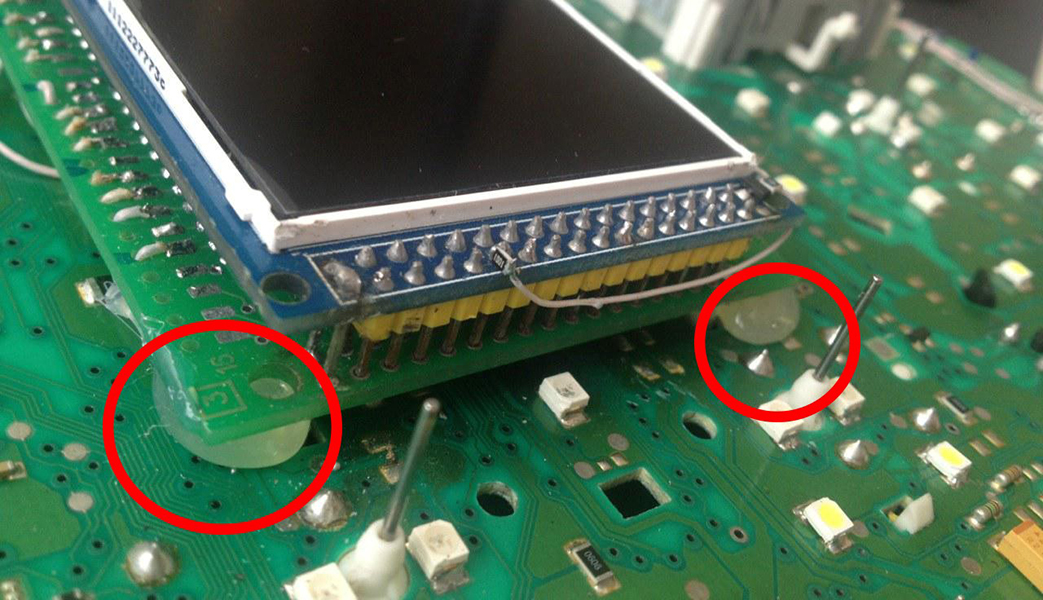

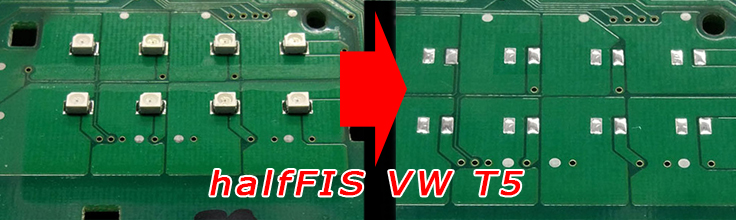

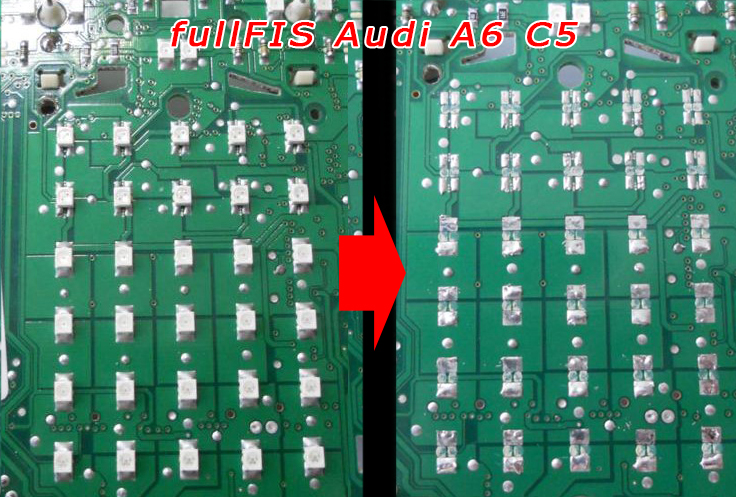

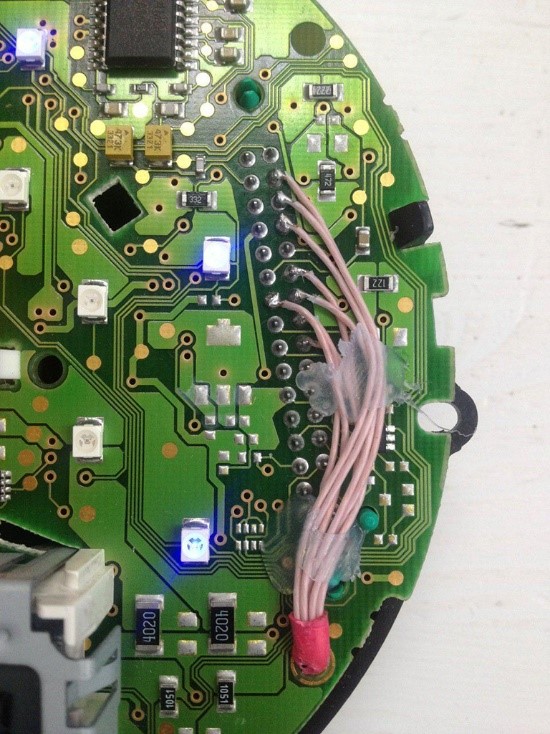

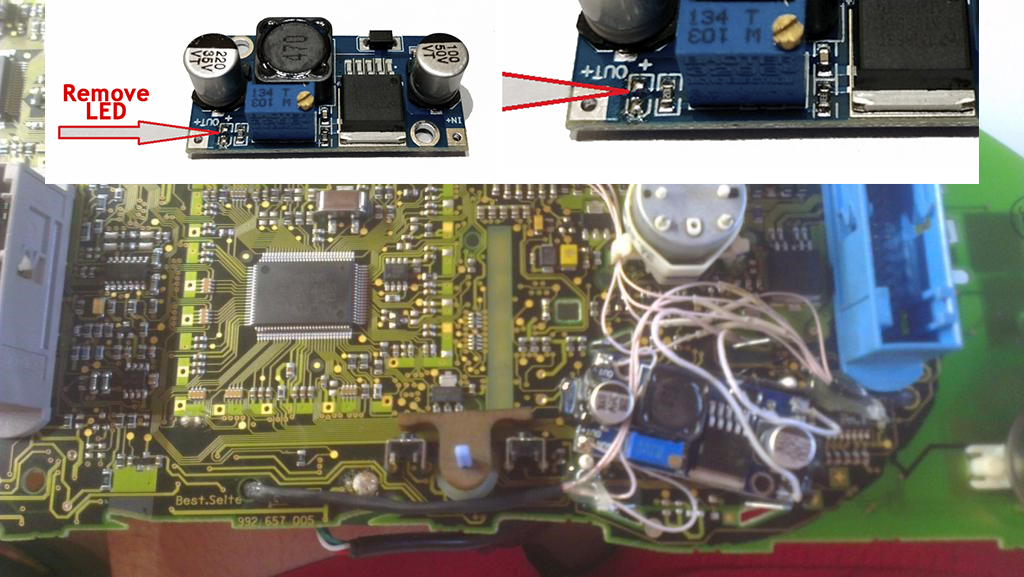

9.

Then

you need to remove all the LEDs that are were under the standard display

We

make sure that there are no jumpers made of tin.

After

removing the LEDs, clean the board of the residues of tin and rinse with alcohol

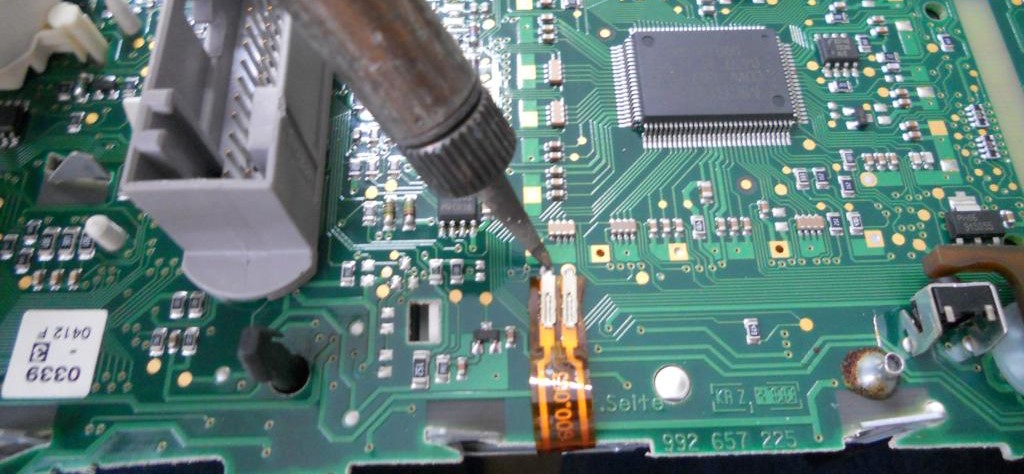

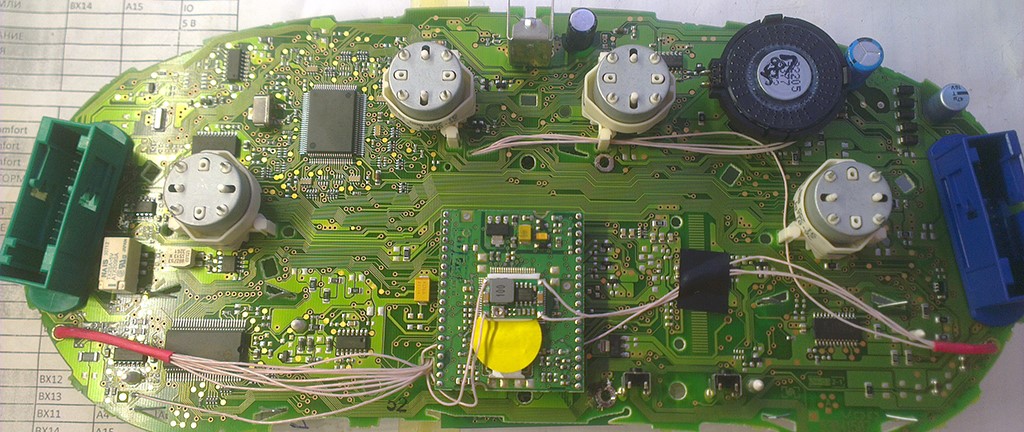

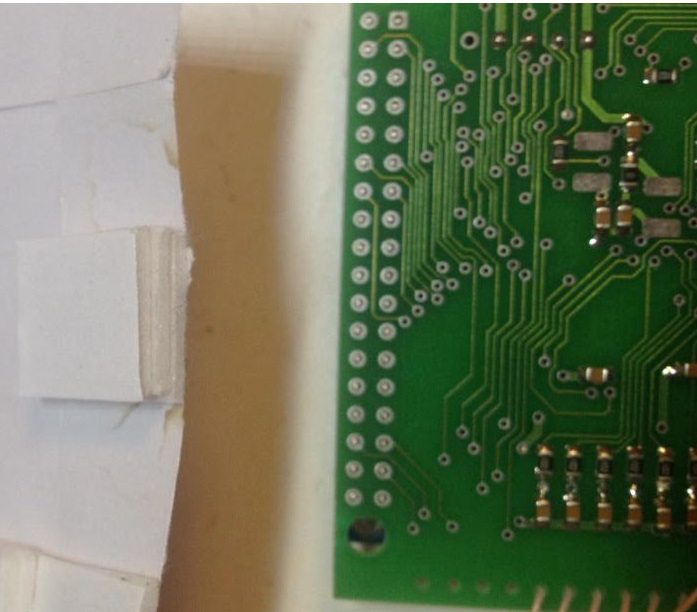

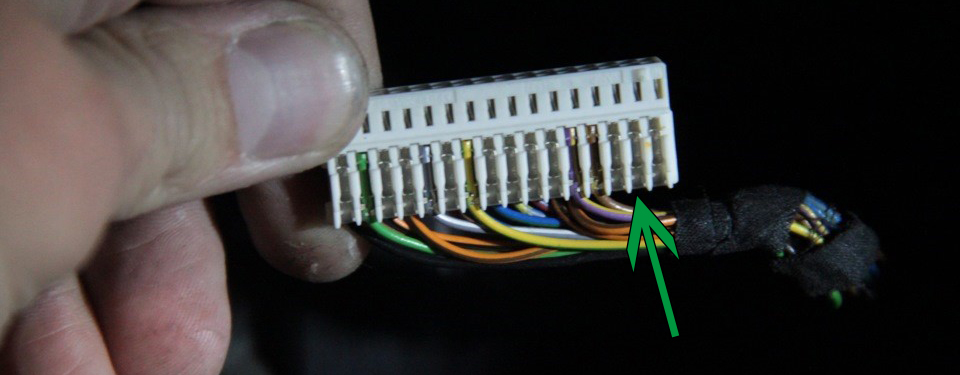

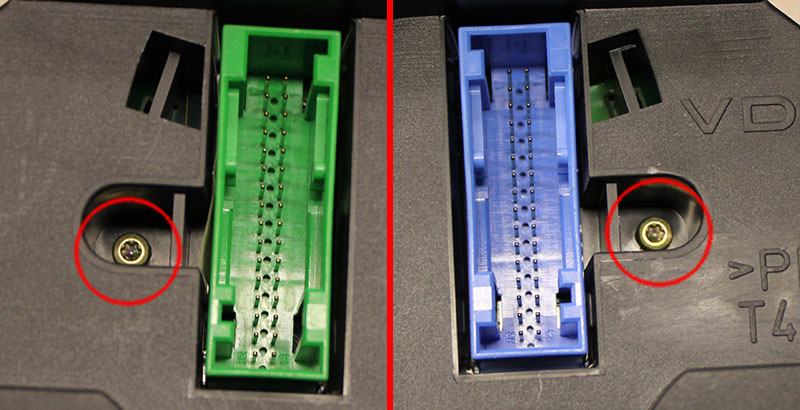

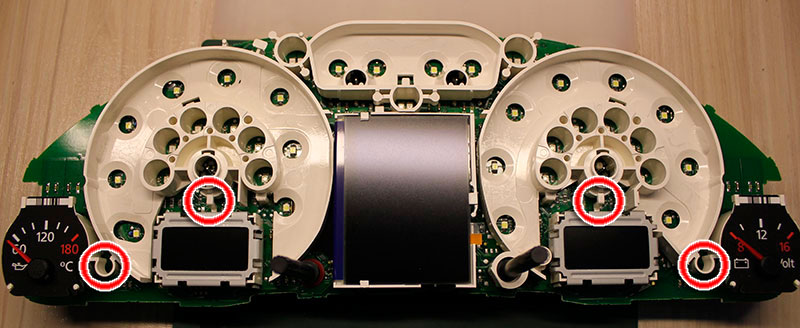

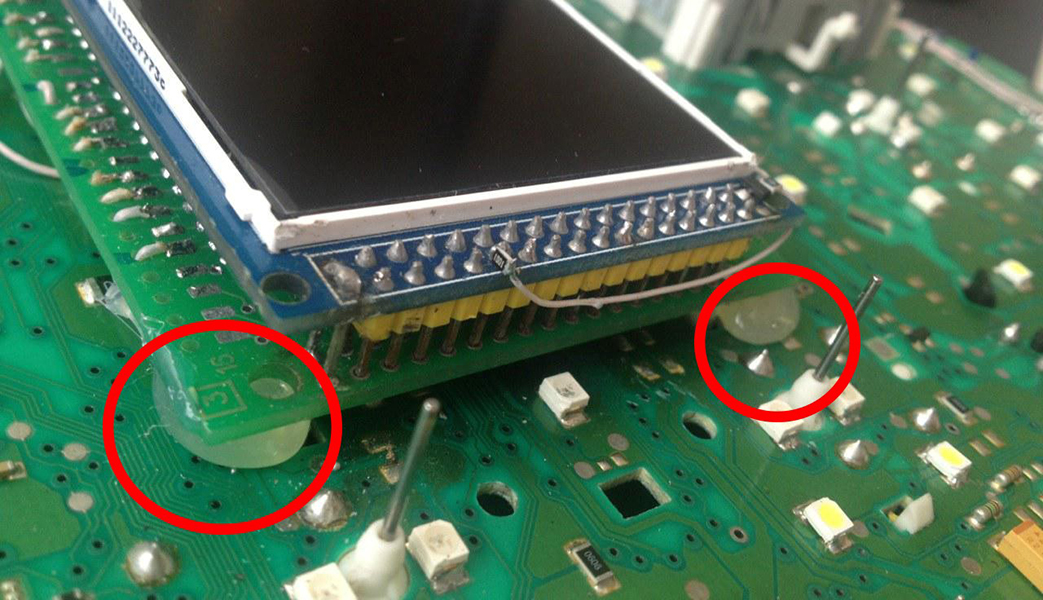

7.

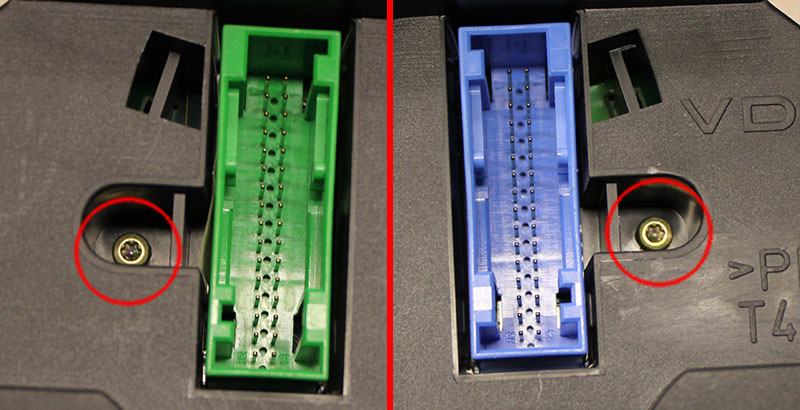

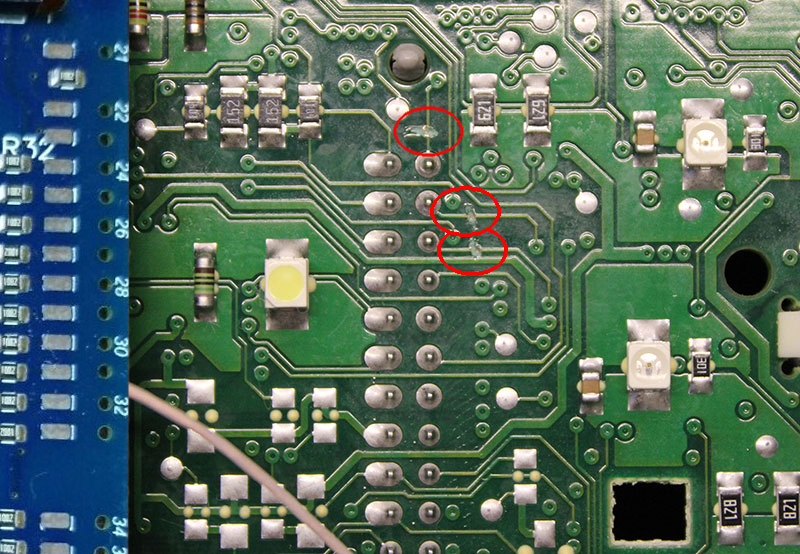

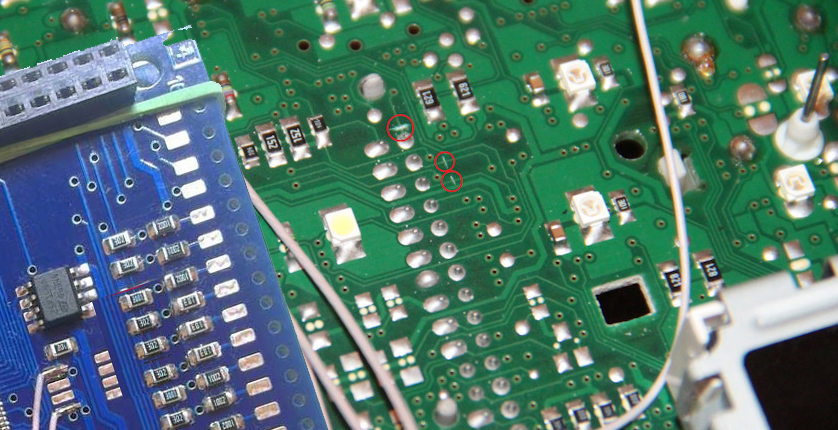

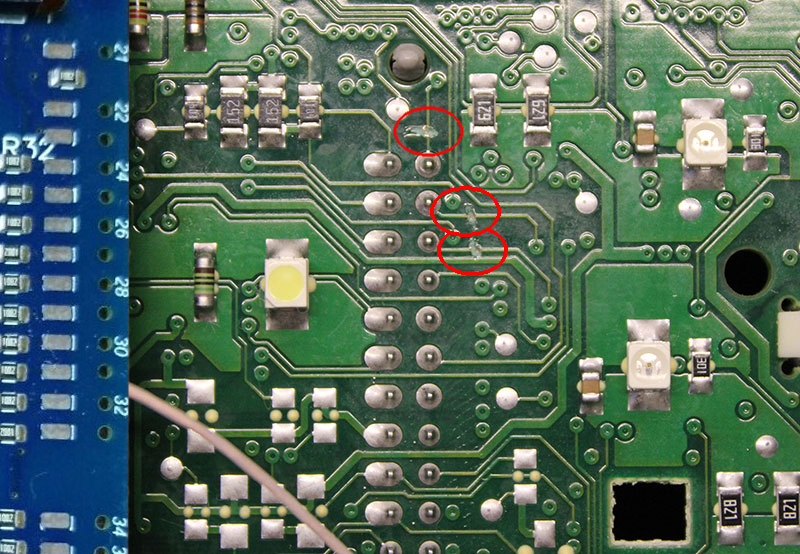

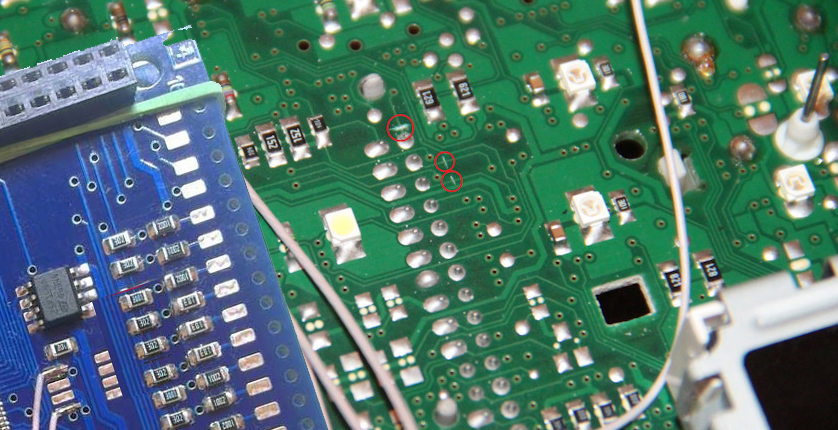

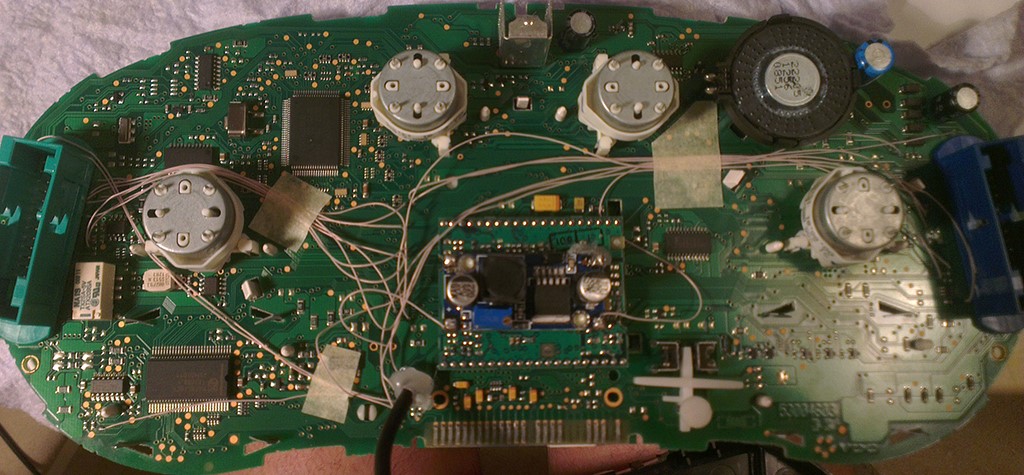

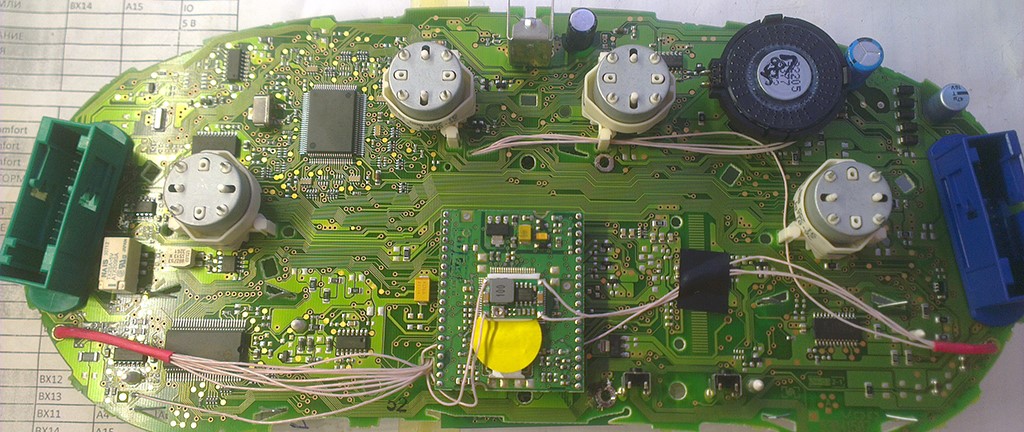

VERY IMPORTANT:

For instruments with a BC installed, it

is necessary to

find and trim

tracks from the pins of the control of the standard BC on the

board

of the instrument panel (from the pins

17, 18, 19 of the grey

connector)

Below are photos from some instruments.

On your device, the tracks may be located elsewhere

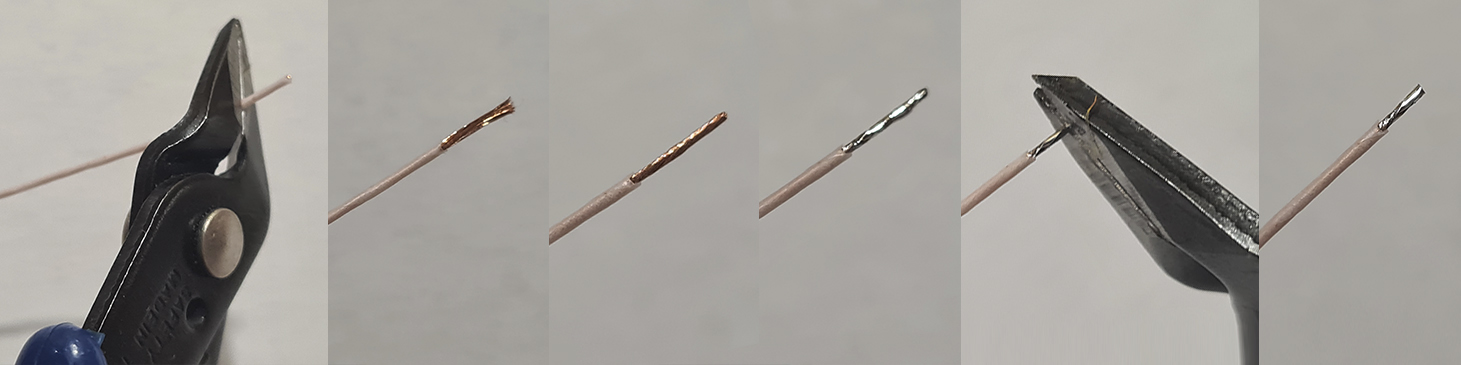

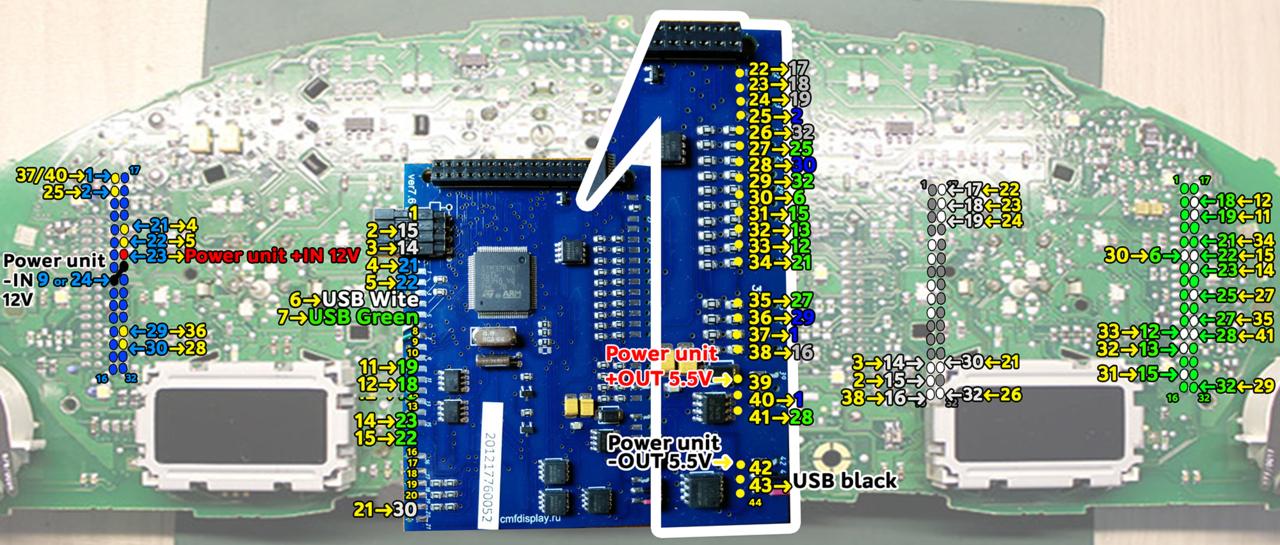

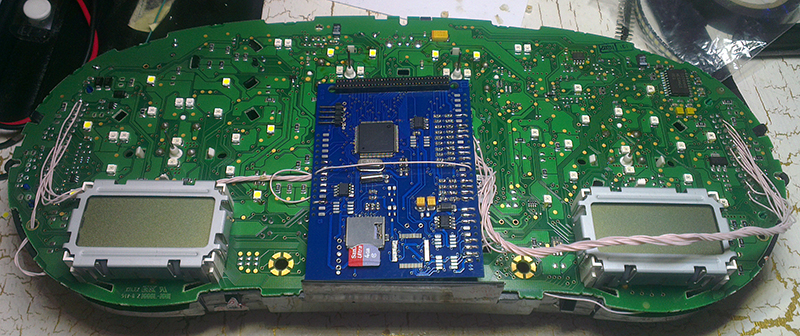

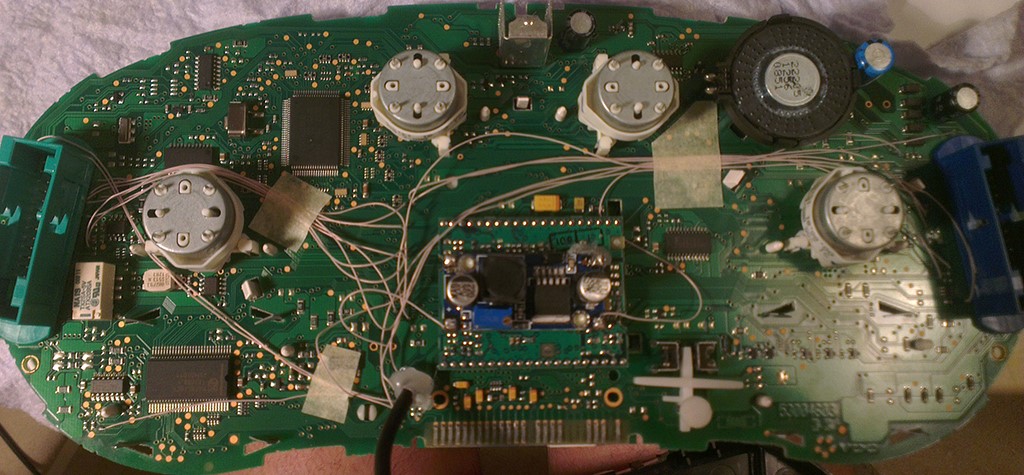

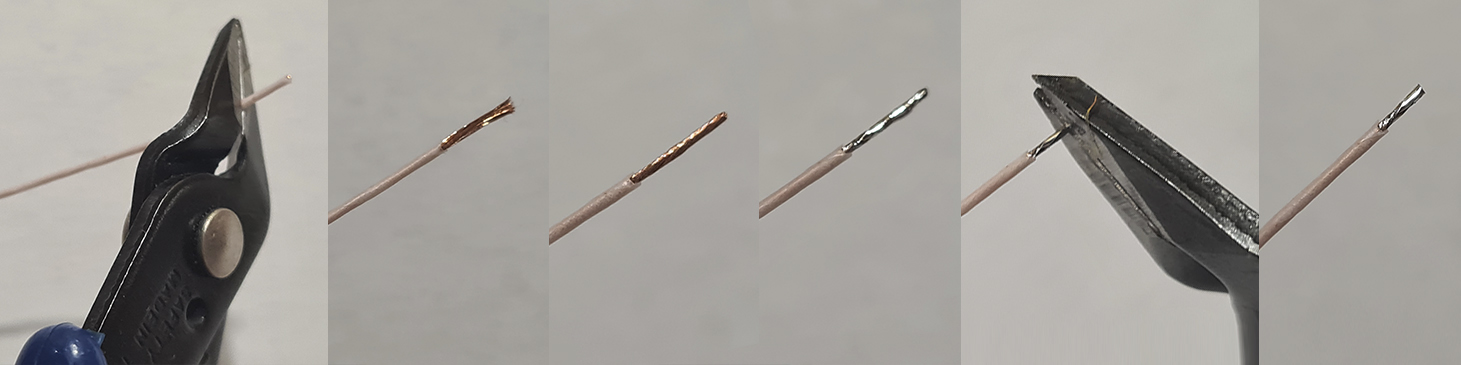

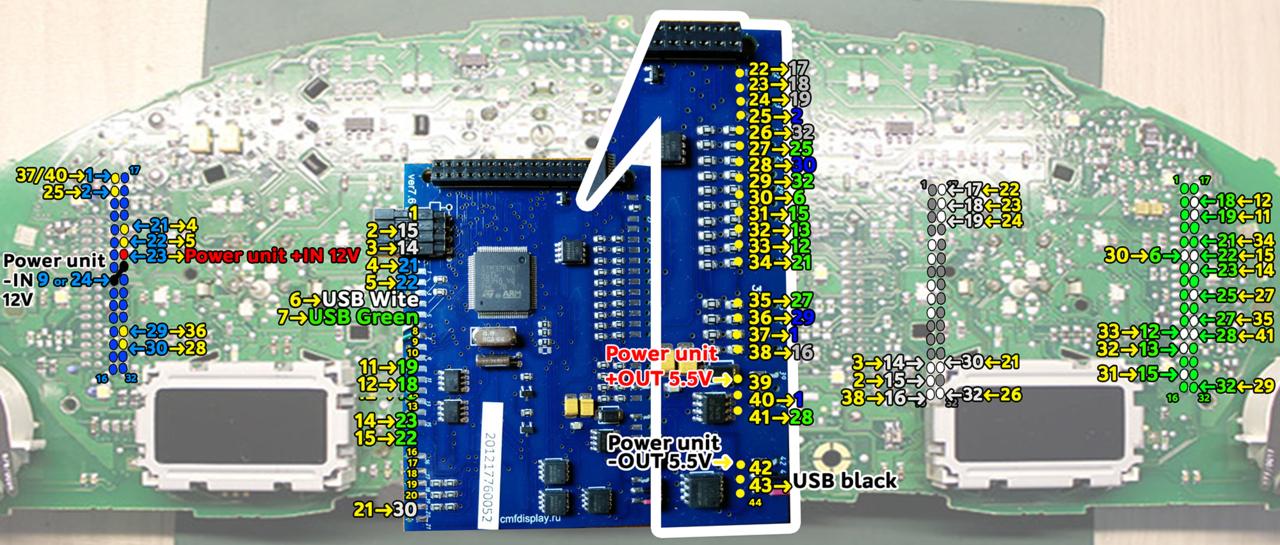

10. We

start to build wires according to the table. Wires

are cleaned of

Isolation and

twisting, ludim and cut off excess.

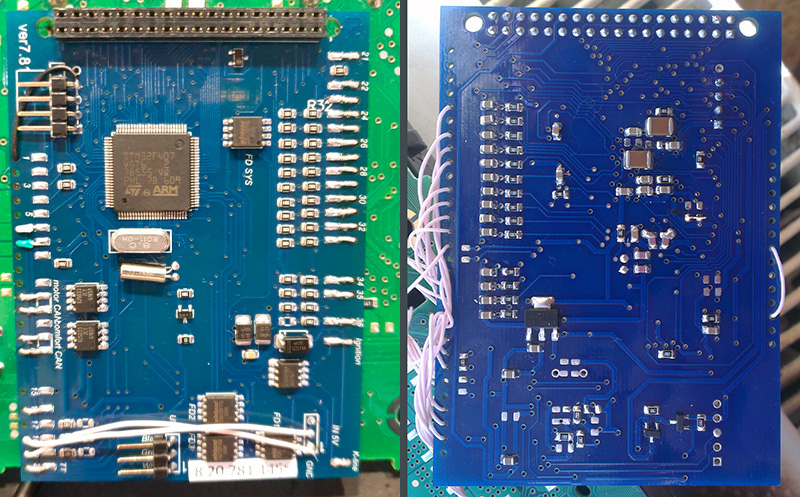

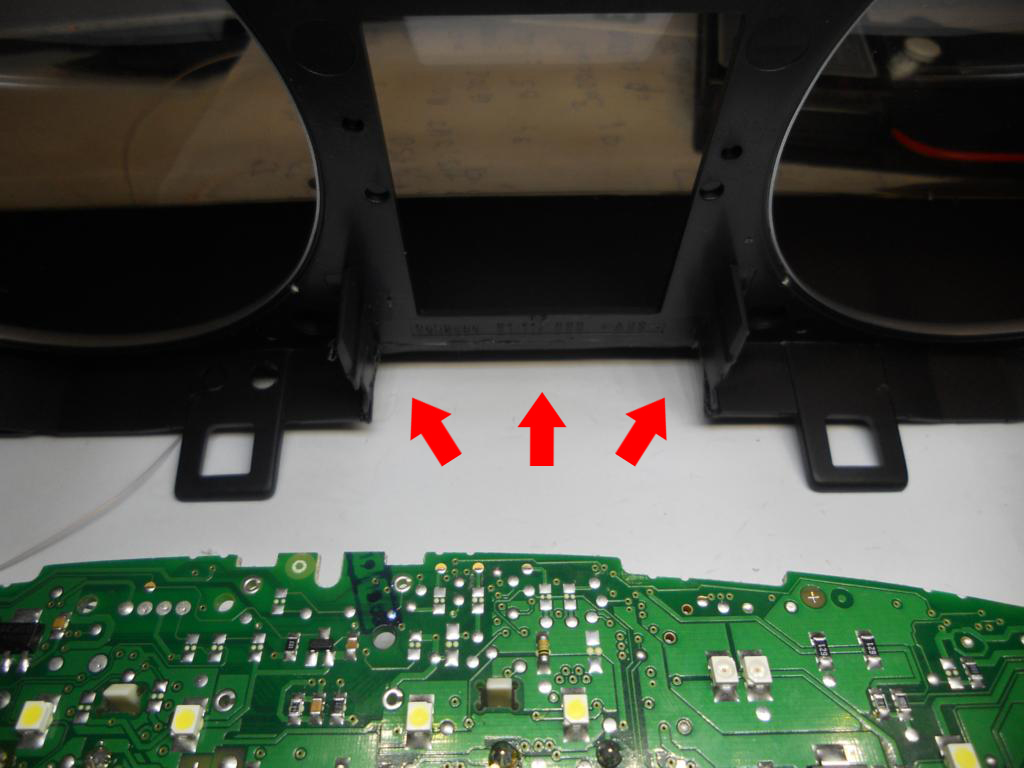

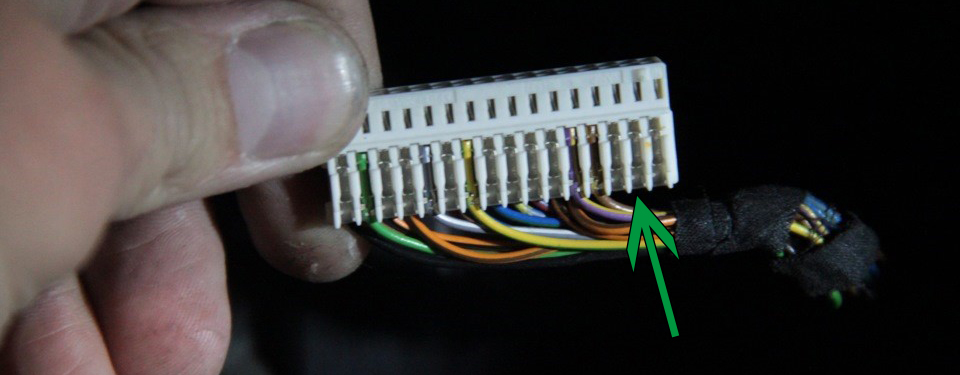

12. Through the

holes in the board of the device, we extend the wires to the blue

And green

connectors.

13. Using the

tester, we find the wires we need and solder them to the feet

connector

according to the table.

Full size

image

It is necessary to twist the wires of the

connection to the CAN-bus into a spiral.

Lay the wires in such a way that they

do not interfere with the installation of white

Light diffuser.

17. Wires should

be pulled from the back side Or

as shown above,

So they do not

interfere with the assembly of the device. So

it's not right!

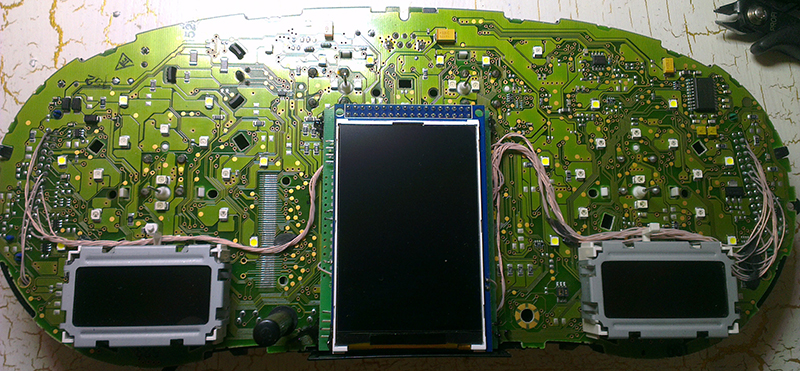

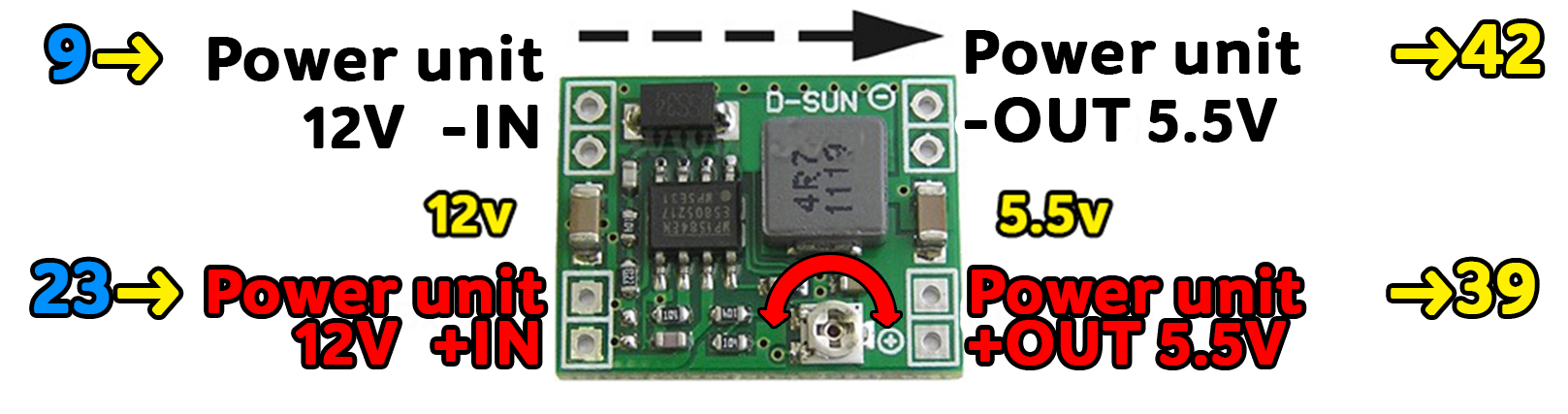

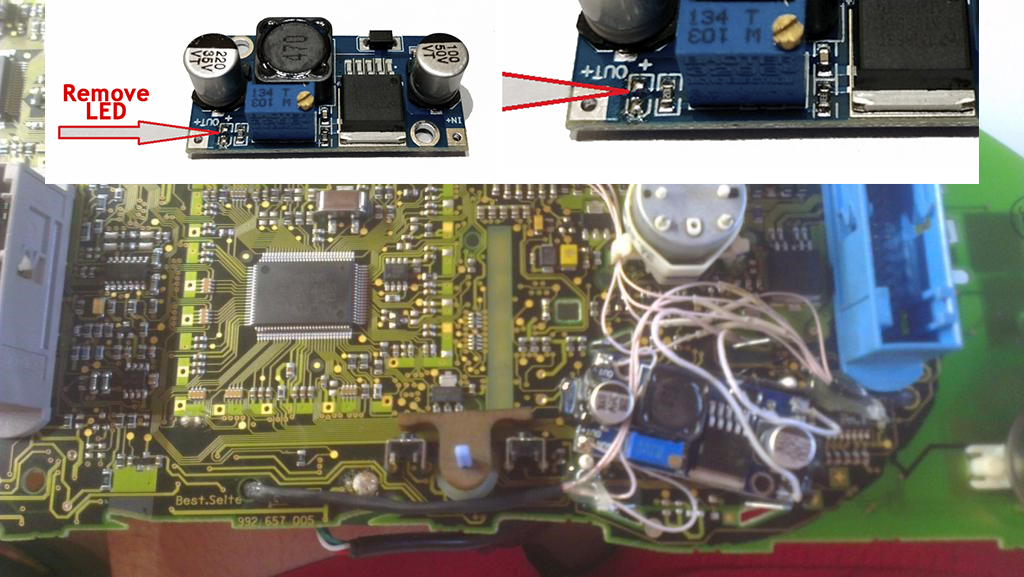

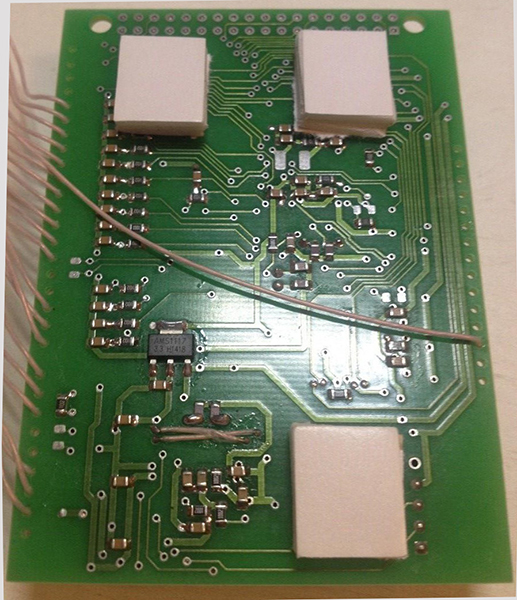

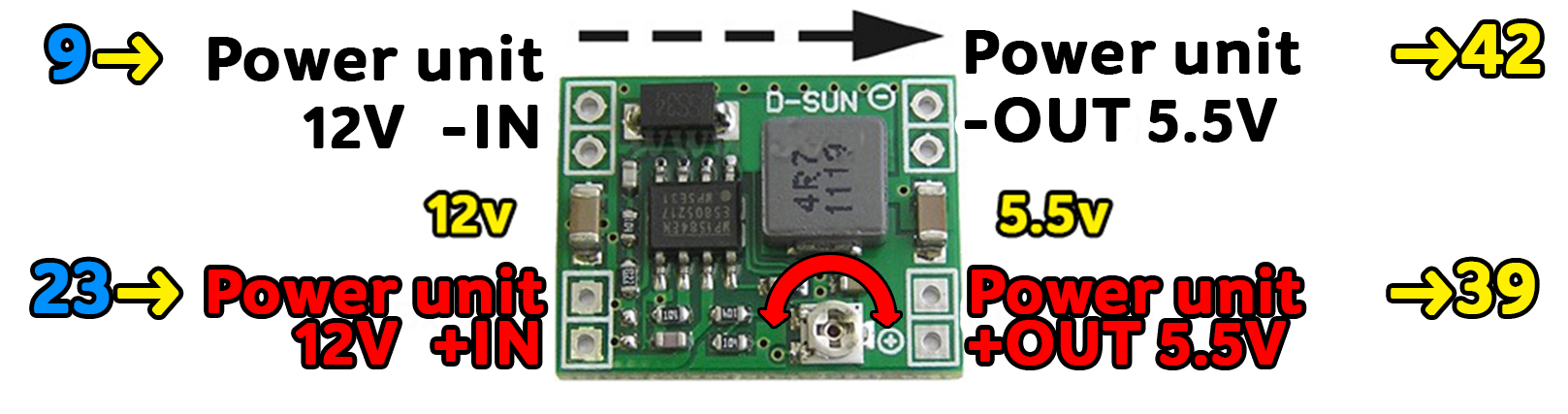

Attention!

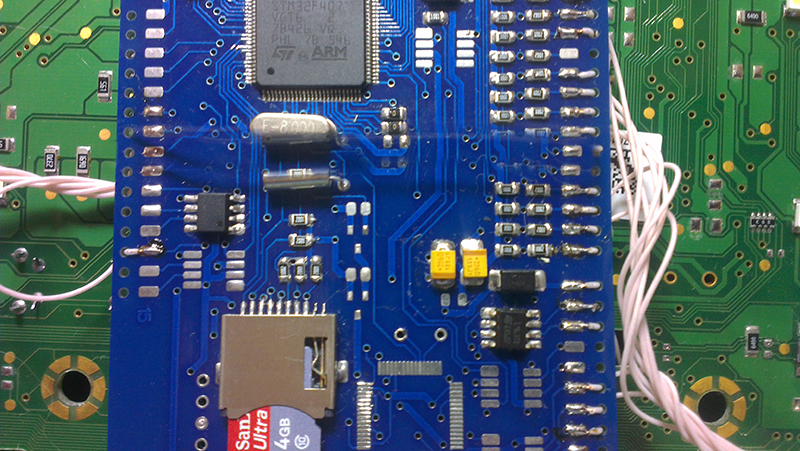

18. Before

installing the power supply, you need to solder the wires to it

contacts + IN - IN and

+ OUT - OUT ,

then apply a current of 12V to + IN - IN ,

and connect

the + OUT - OUT wires

to the tester.

Now we need to

adjust the output current. Using

a small flat screwdriver

slowly

rotate

the special metal knob (figure 1 in the picture.) Clockwise

Arrow, until, at us

on the tester will not appear 5,5v in an output voltage.

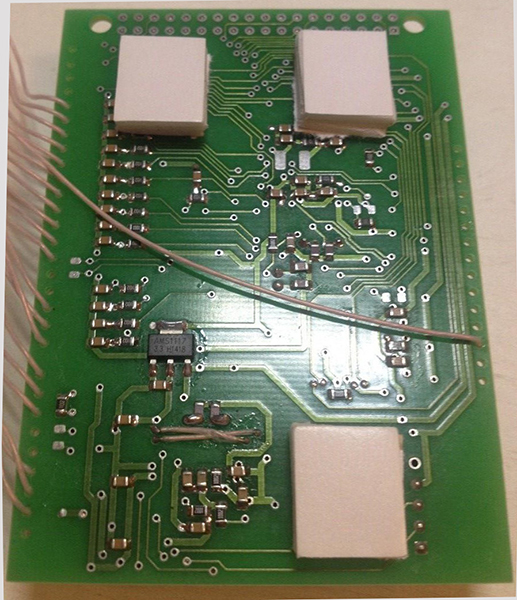

Next we place the

power supply unit on the back side, we bring to its contacts the

wires from the blue connector.

9-pin of the blue connector

is connected to the e - IN on

the power supply board.

23 the leg of the blue connector

is connected to + IN On

the power supply board,

Contact

- OUT Connects

to 42 pin MFD

+ OUT Connects

to the 39 pin MFD,

Choose the place of

installation of the power supply so that

during assembly it does not

interfere. Here

are the possible

Options:

Attention!

After wiring, lay it so that they do not interfere with further

assembly.

Need

to

call all contacts and check

on the table to avoid confusion anywhere.

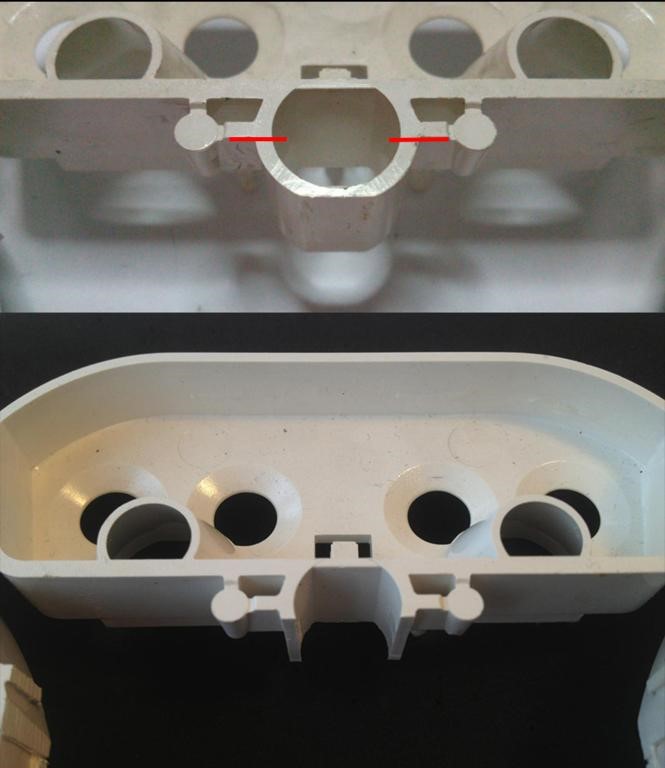

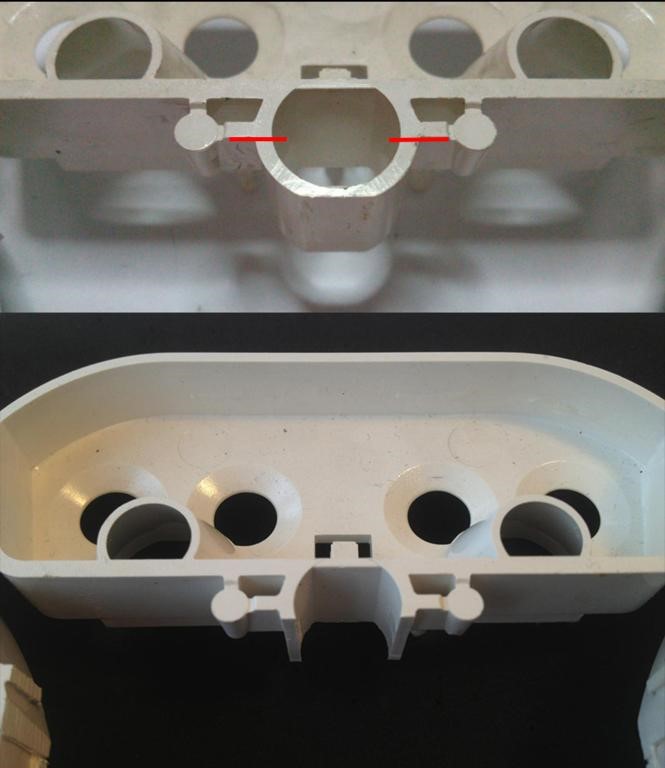

20. Cut off the

main beam guide part.

On the red line.

Leave the

semicircle.

21.

Bite off the protruding part!

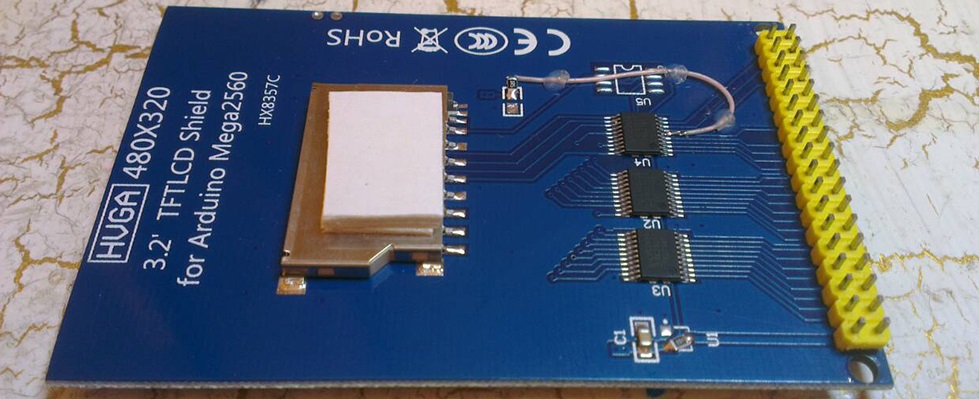

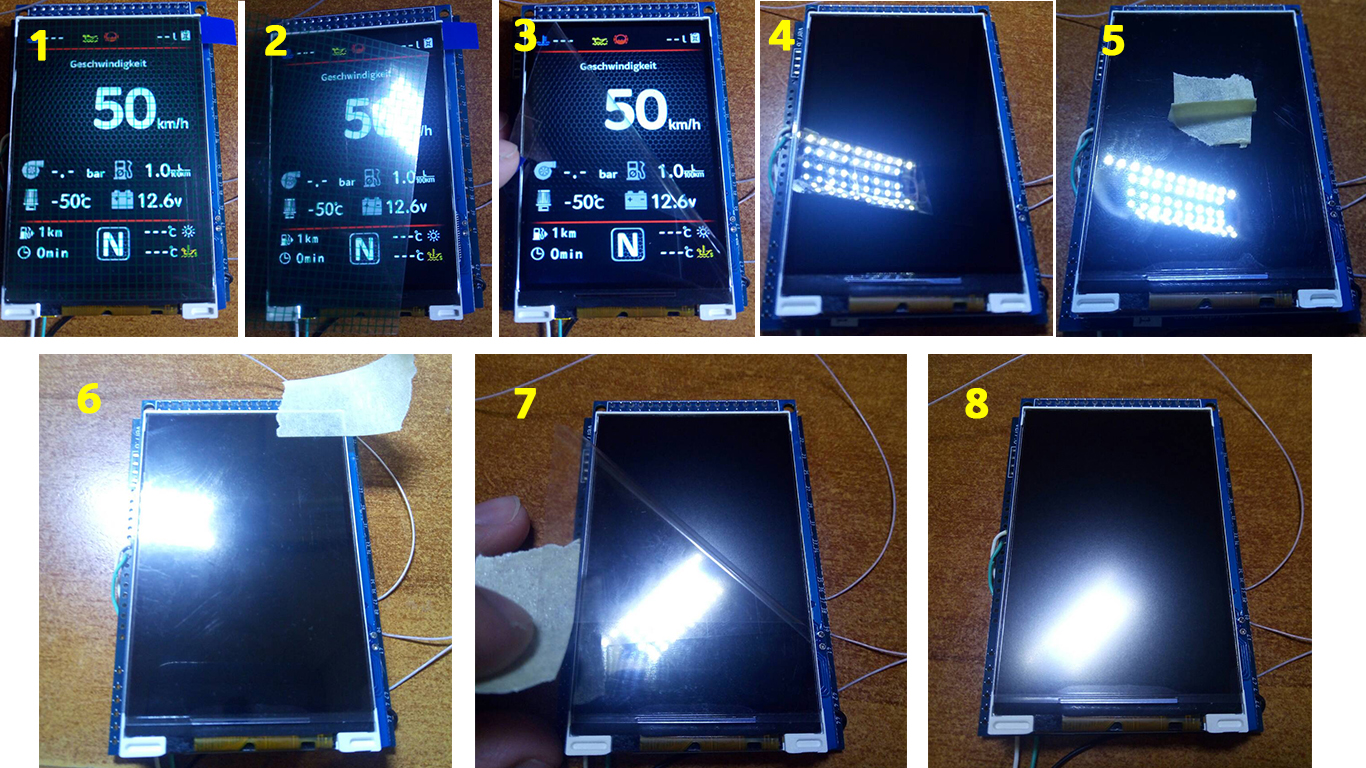

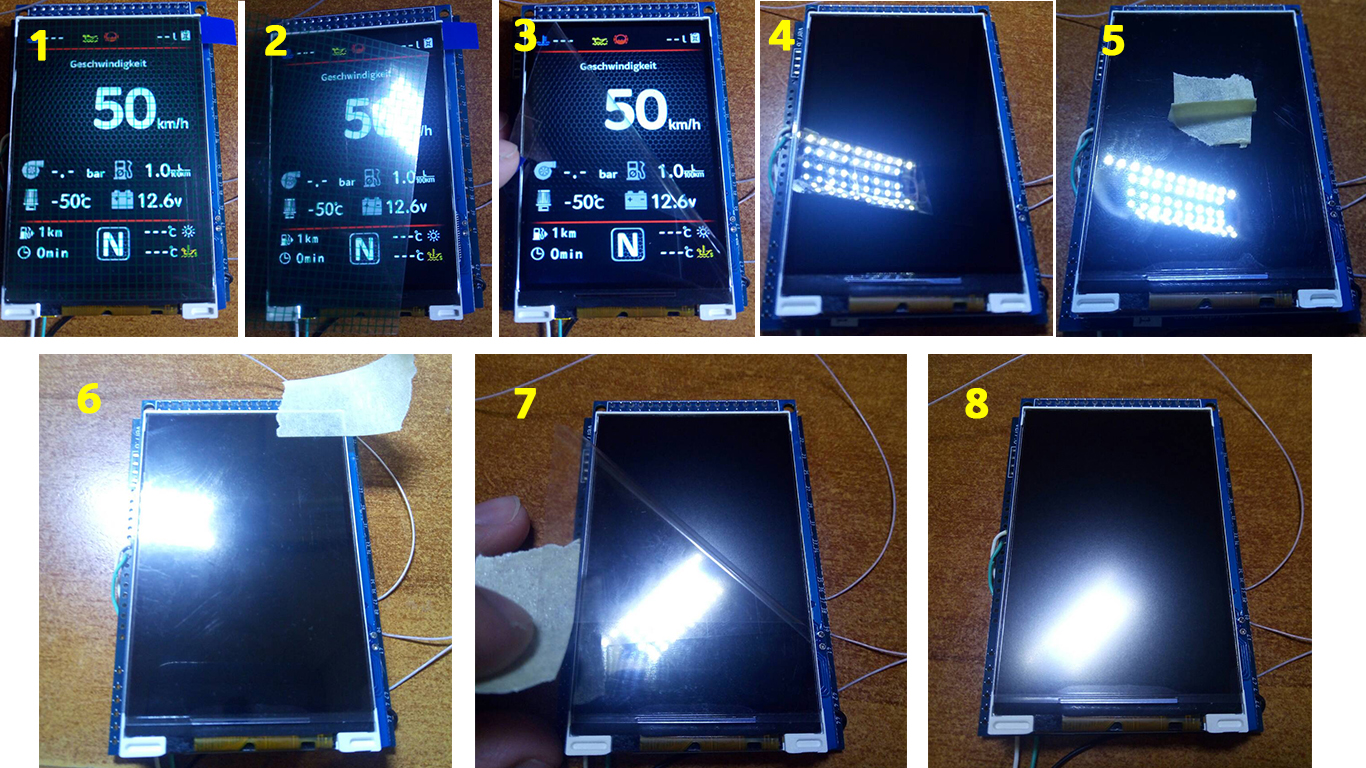

22. Before

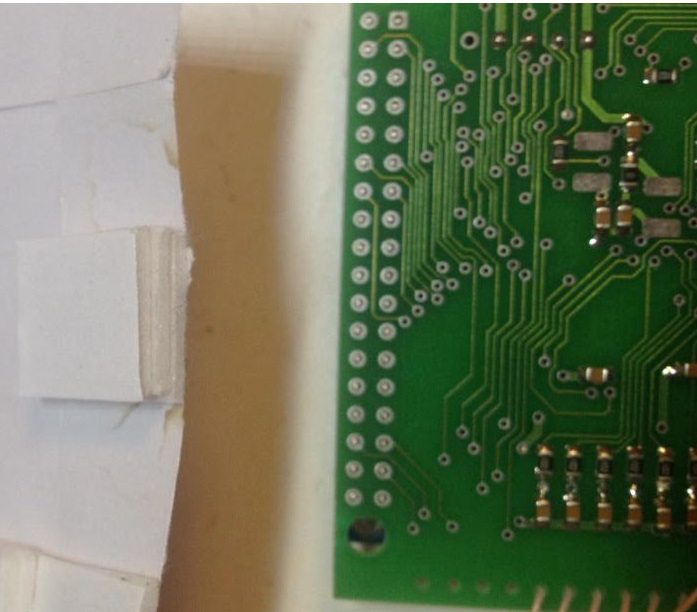

installing the display, you need to glue two-way

cattle into three

layers on the back of the display to lock the display.

Attention! you do not need to attach modules to the board!

It is enough simply to remove an additional support from a

double-sided adhesive tape

without removing the protective layer

from the side of the module board.

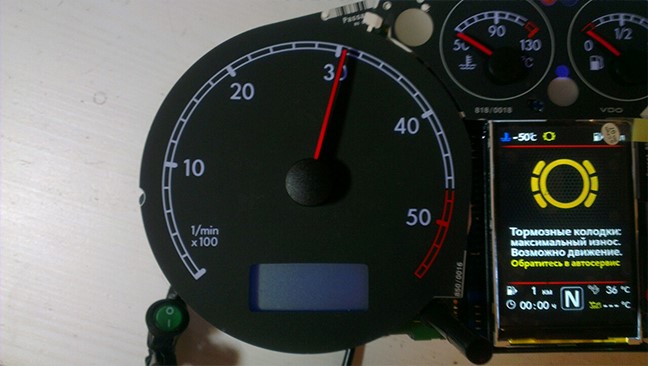

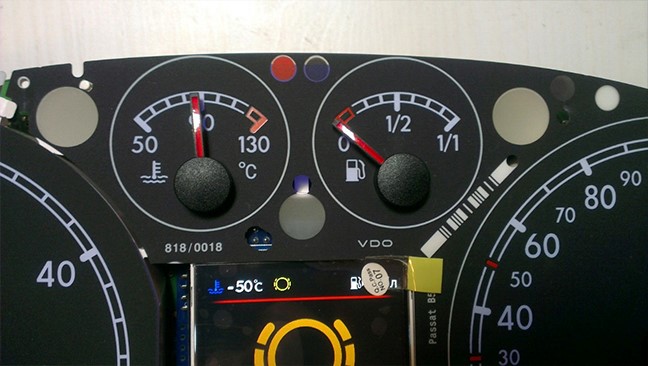

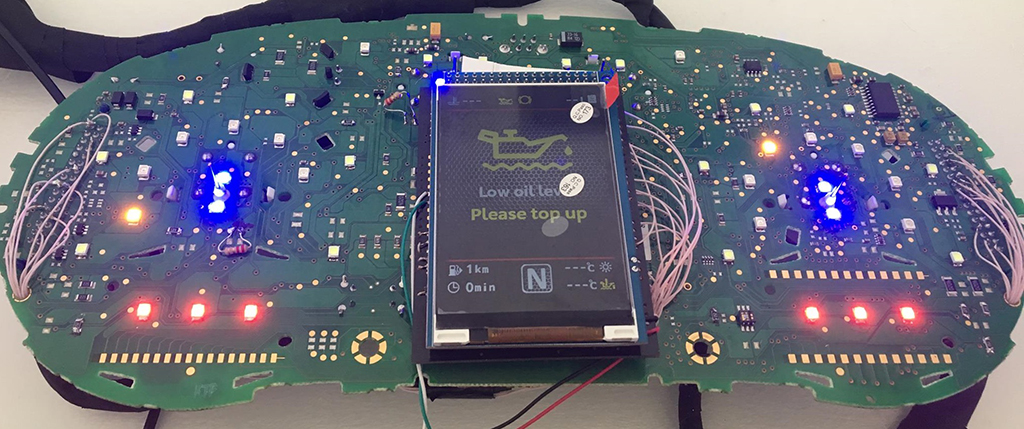

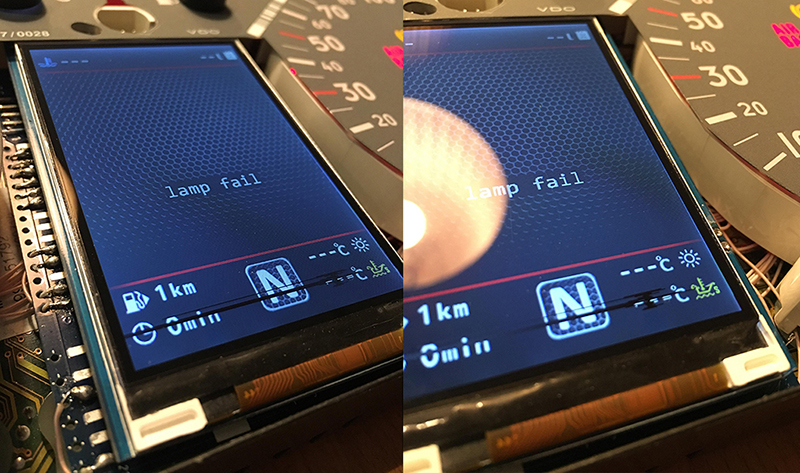

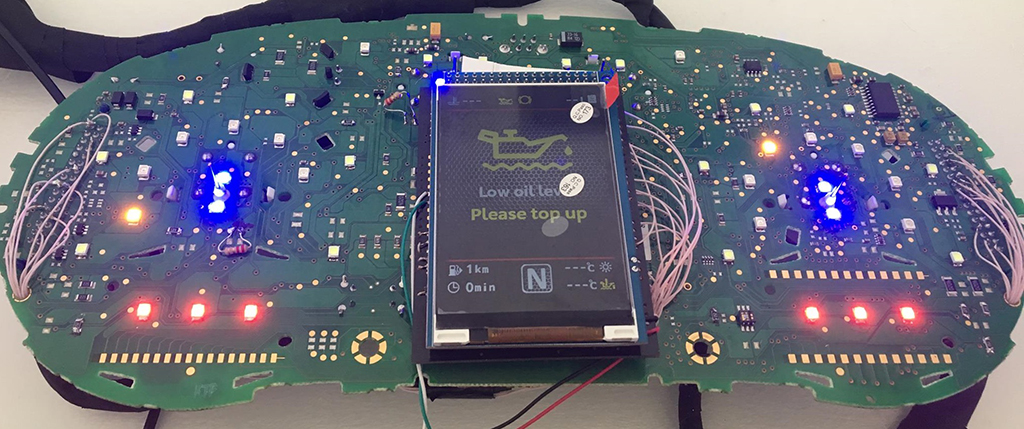

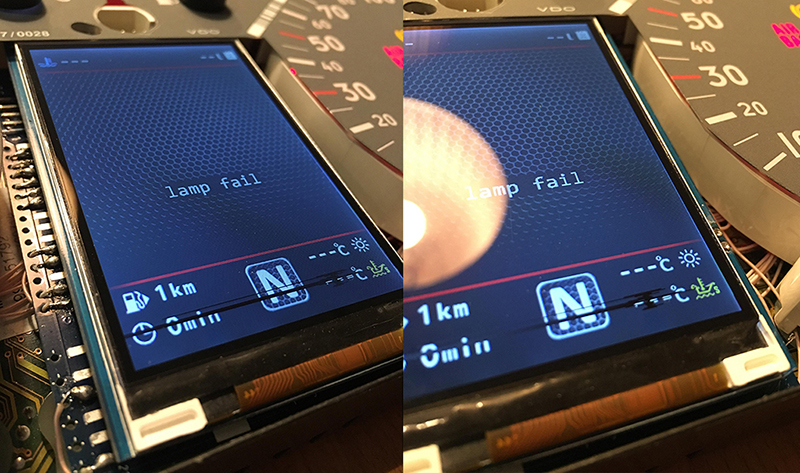

After you solder the wires

and set the display to its place,

you need to

test the MFD performance in the car to make sure everything is properly installed

and working well.

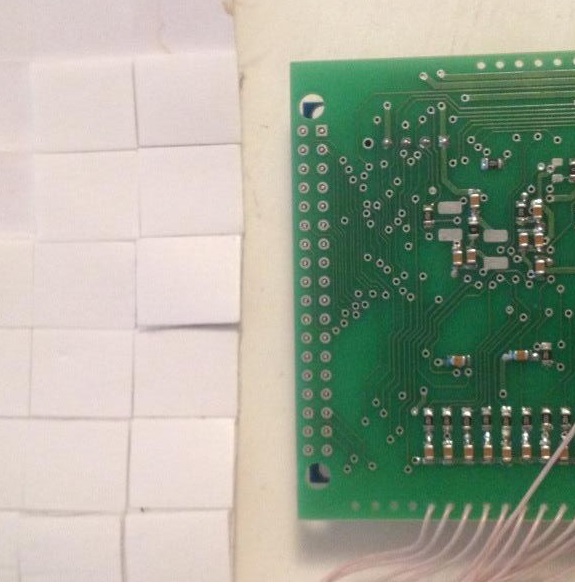

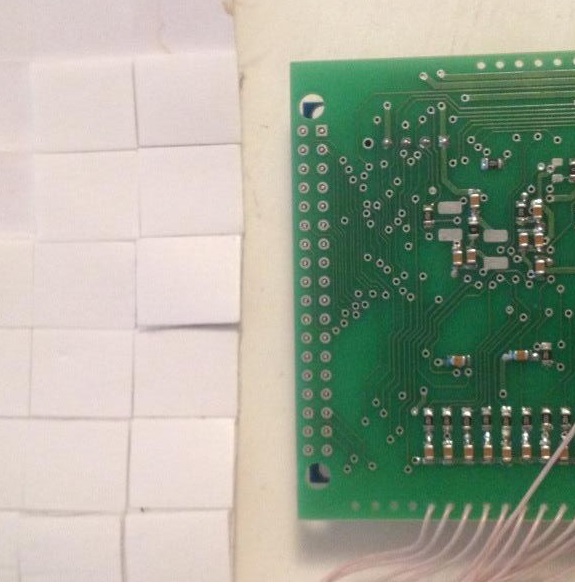

23. We take

double-sided adhesive tape on a foamy basis, cut the squares 1cm X 1cm.

24. We collect

these squares in 3 floors.

25. And we place

them so that we do not have anything to do with mounting the module

on the board

26. Place the

module so that it is placed in the window of the device

27. For greater reliability, when the module is already installed on

the board,

and you calibrated it in the window so that there were no distortions, it is

better to fix it.

Its hot glue along the edges of the module.

Next, you need

to glue the matte protective film so that the display does not glare

in the sun.

Attention!

Be sure to stick the film!

Otherwise, you may damage the display!

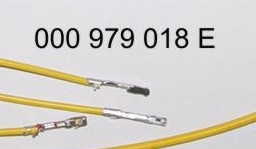

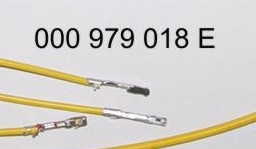

T

o connect the boost pressure control.

You will need to add one PIN to the dashboard

32 pin

grey connector.

And the second end of

the wire needs to be connected

the signal wire of

boost sensor,

on this wire at idle should be 1.6v,

with increasing PRM the voltage should

increase.

If your motor is not in the table, find the boost sensor under the

hood, it has 4 wires,

Use a multimeter to determine the signal wire, remember its color

and find this wire in the ECU connector

Usually it is blue - gray wire

(blue with a gray bar) to the incoming

On the 101st contact of a smaller brain connector.

On

diesel engines (AVB and others):

- 71st

contact of the motor

brain, green - red Wire

(green with a red stripe).

On

petrol (AWM and others):

- 101st

contact of the motor

brain, gray - blue wire

(gray with a blue stripe).

In

general, as far as I understand, at all B5-x diesel 1.9T

supercharging is connected to the 71st

And

the gasoline 1.8T is connected to the 101st contact. The

color of the wire can vary depending on the year / engine.

|

BES |

2.7T |

T121 |

101 pin |

blue-gray |

|

AJM |

1.9TD |

T121 |

71 pin |

yellow-black |

|

AKN |

2.5TD |

T121 |

71 pin |

yellow-red |

|

AUY |

1.9TD |

T121 |

71 pin |

yellow-black |

|

BQW |

2.0TD |

T94 |

78 pin |

green-red |

|

AWT |

1.8T |

T121 |

101 pin |

blue-gray |

|

AVG |

1.9TD |

T80 |

40 pin |

yellow-green |

|

AWM |

1.8T |

T121 |

101 pin |

blue-gray |

|

AFN |

1.9TD |

T121 |

70 pin |

green-red |

|

AWD |

1.8T |

T121 |

101 pin |

blue-gray |

|

AVB |

1.9TD |

T121 |

71 pin |

green-red |

|

AWP |

1.8T |

T121 |

101 pin |

violet-gray |

|

AVF |

1.9TD |

T121 |

71 pin |

green-red |

|

AUM |

1.8T |

T121 |

101 pin |

violet-gray |

|

AWX |

1.9TD |

T121 |

71 pin |

green-red |

|

AUQ |

1.8T |

T121 |

101 pin |

violet-gray |

|

AHF |

1.9TD |

T121 |

71 pin |

yellow-black |

|

ARZ |

1.8T |

T121 |

101 pin |

violet-gray |

|

ALH |

1.9TD |

T121 |

71 pin |

yellow-black |

|

ARX |

1.8T |

T121 |

101 pin |

violet-gray |

|

ARL |

1.9TD |

T121 |

71 pin |

yellow-black |

|

ANB |

1.8T |

T121 |

101 pin |

blue-gray |

|

ASV |

1.9TD |

T121 |

71 pin |

yellow-black |

|

APU |

1.8T |

T121 |

101 pin |

blue-gray |

|

ASZ |

1.9TD |

T121 |

71 pin |

yellow-black |

|

APB |

1.8T |

T121 |

101 pin |

blue-gray |

|

ATD |

1.9TD |

T121 |

71 pin |

yellow-black |

|

AMB |

1.8T |

T121 |

101 pin |

blue-gray |

|

AXR |

1.9TD |

T121 |

71 pin |

yellow-black |

|

|

|

|

|

|

|

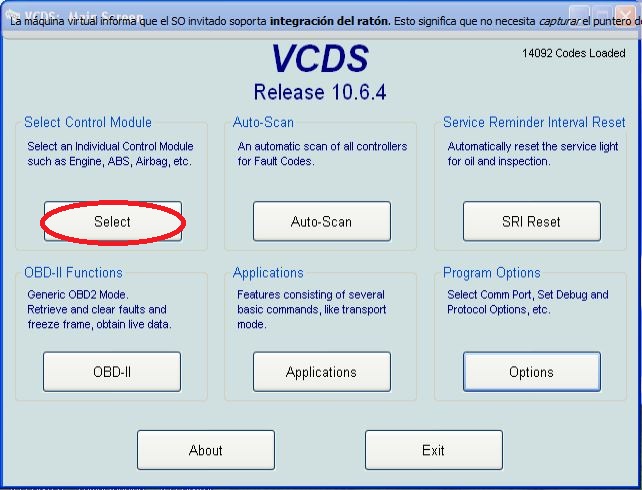

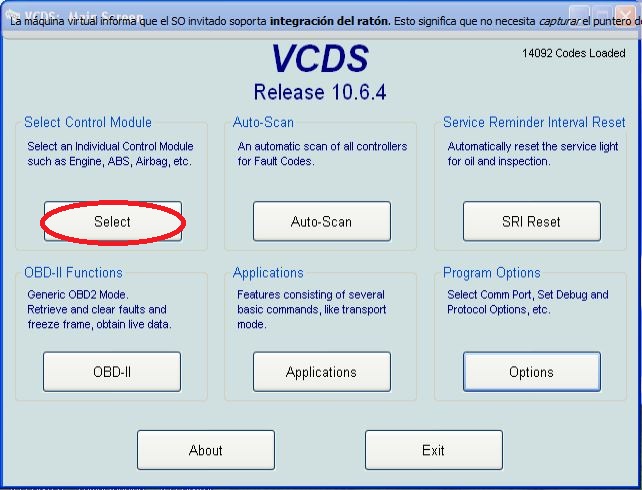

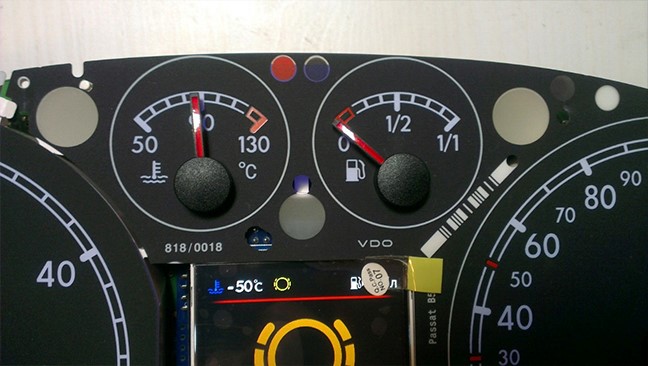

And then we collect everything in

the reverse order without forgetting

to calibrate the

needles

with the help

of the WAG-com.

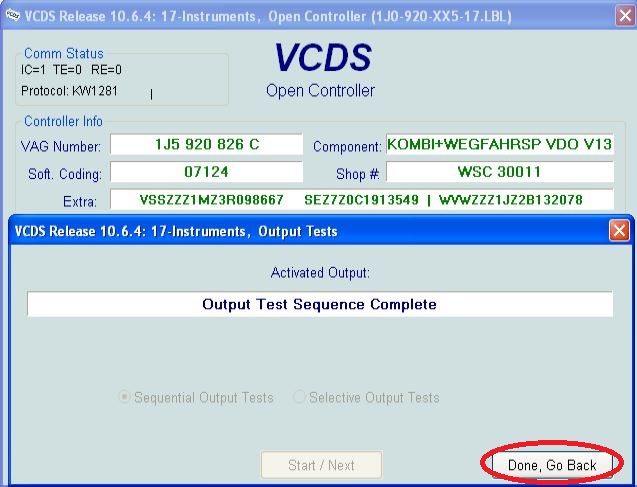

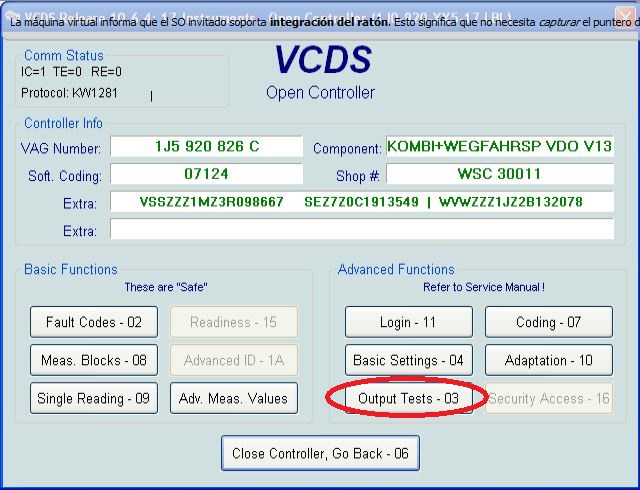

I. To

do this, connect the device to the machine without installing the

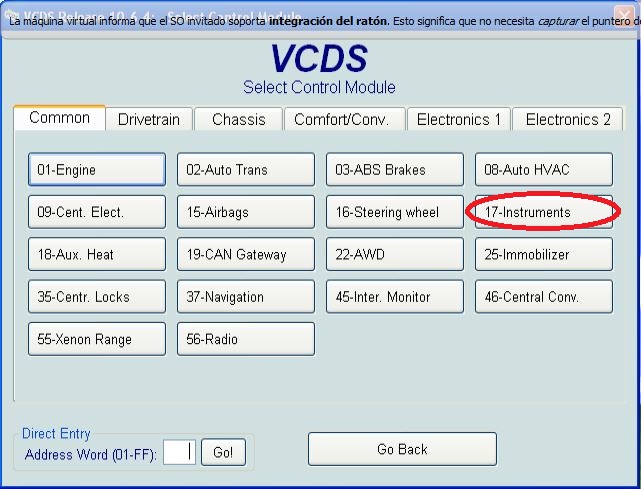

glass, connect the VAG-com,

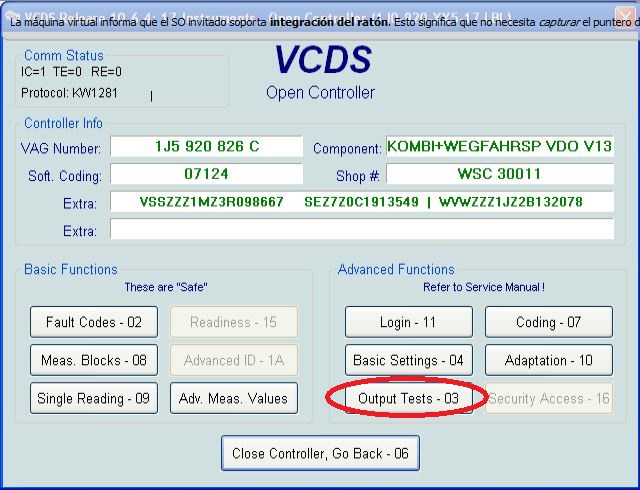

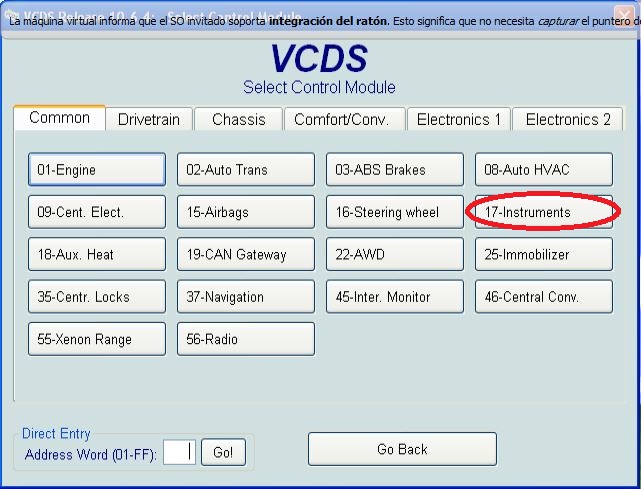

Ii. Go

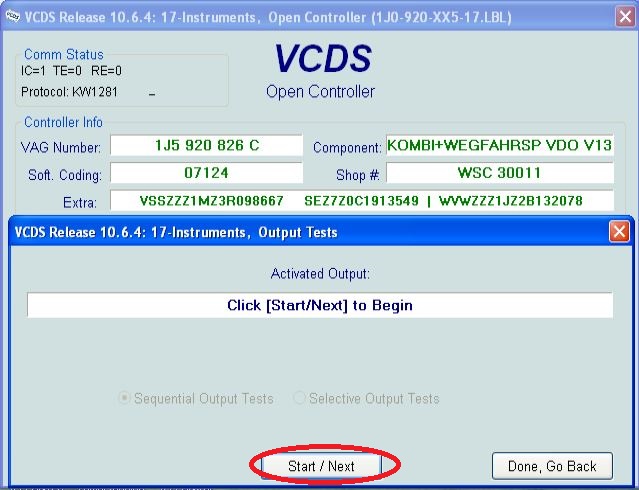

into the 17-unit dash panel

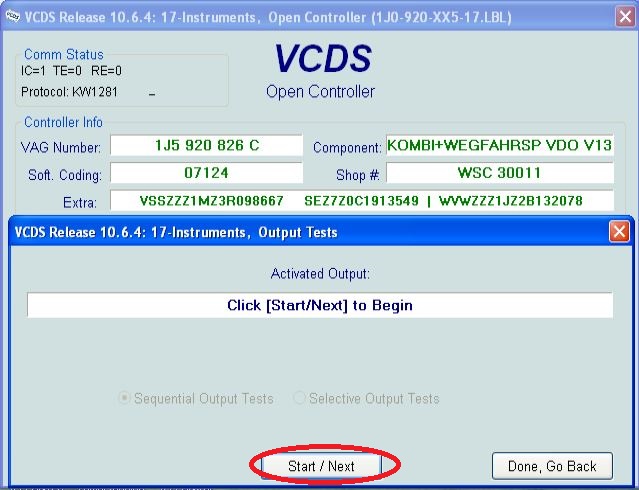

Iii. Select

test performers.

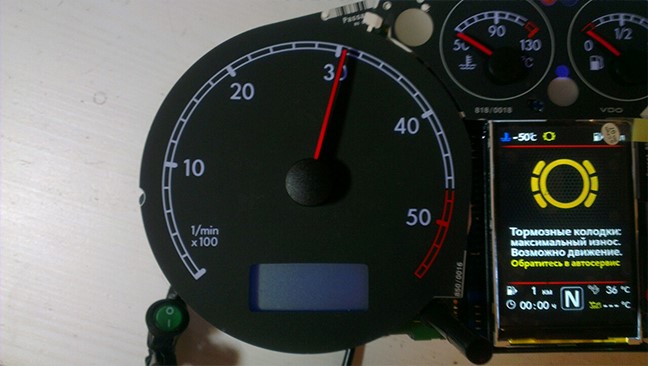

Iv. Choosing

in turn a tachometer, temperature and the rest, the arrows in turn

will be

Do a turn on

the whole scale, and then freeze on:

1. Tachometer

- 3 thousand revolutions

2. Pace. Coolant

- middle

3. Fuel

level - middle

4. Speedometer

- at 100 km / h

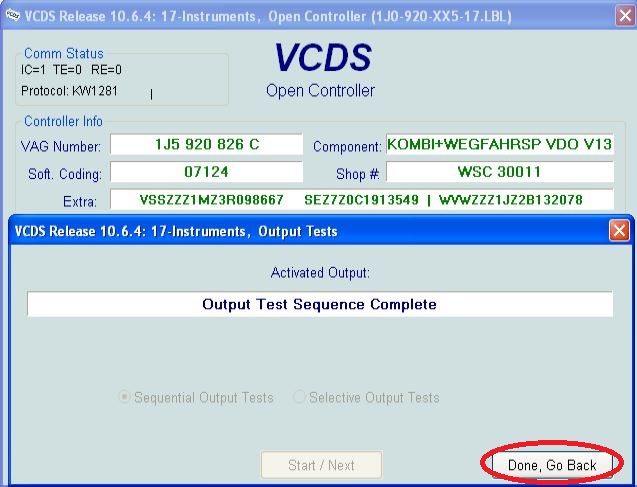

V. Then

turn off the power from the device!

Vi. And

set the arrows correctly rotating them in the desired direction.

Vii. Then

check everything again

Viii. You

can not turn the needles too quickly correcting the position, you can

to

damage the motors of the

needles

Ix. You

can not turn the arrows when there is power on the device.